What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

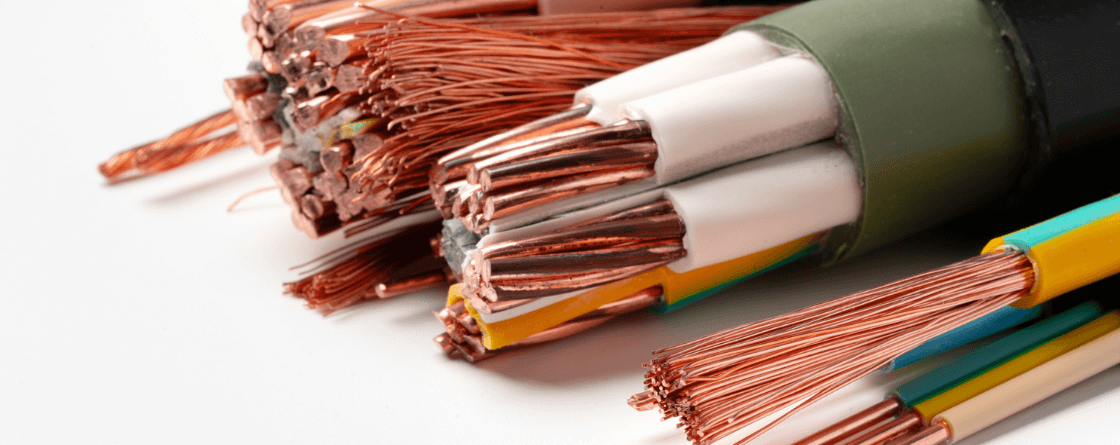

Keeping critical infrastructure online and mission systems ready needs more than components. It requires domestic build capacity you can audit. In the UK, Cable Manufacturing underpins defence communications, C2/C4ISR networks, rail and power systems, and the data‑centre and telecoms backbones that carry national traffic. Building and testing assemblies in the UK via Cable Manufacturing improves assurance, shortens change cycles, and gives programmes evidence they can defend at review.

For defence, CNI and national networks, keep cable manufacturing in the UK. We host line audits on request, provide a test pack per assembly, and handle drawings and data under controlled access within our QMS. When priorities shift, we aim for same‑shift route‑card/build‑record updates with engineer sign‑off to keep acceptance on schedule.

In short, UK cable manufacturing gives buyers auditability, evidence, and speed. From quote to acceptance, fewer surprises. Get a clear test plan, documentation checklist, and next steps for your sector. Contact us.

Avionics looms, vehicle harnesses, sensor and comms interconnects, and ground support equipment depend on repeatable workmanship and measured test. For platform and mission systems, this means AS9100 discipline, EMI/EMC‑aware design, and materials and terminations selected for the environment (temperature, vibration, ingress, radiation where relevant). Building in the UK can improve audit access and may simplify export‑control compliance for spares and modifications. (See more about defence).

National connectivity depends on fibre and high‑density interconnects. Manufacturing in the UK supports faster change control and swap/repair cycles. Specify IL/RL targets, require OTDR traces (with the event table saved), and specify MTP/MPO cleaning and inspection to IEC 61300‑3‑35 before shipment. (See more about telecoms).

The vast majority of UK international traffic runs over subsea fibre; when a cable faults, repair teams rely on pre‑term kits built on‑shore. UK‑based manufacturing supports those pre‑terms, repair kits, and test evidence for faster acceptance. Local logistics and direct engineering access cut hours off acceptance when you’re restoring service.

Power, rail, water and emergency services rely on cable systems that must operate through environmental stress and cyber‑physical incidents. For rolling stock and trackside systems, specify EN 45545 materials (e.g., EN 45545‑2 for materials and components), vibration‑resistant terminations, and ingress protection validated as an assembly (not assumed from the connector alone). For control rooms and substations, focus on traceability, labelling discipline, and replaceable pre‑terms to compress MTTR. (See more about rail).

UK industrial and security policy emphasises resilient supply chains and sovereign capability for critical systems. Practically, that means:

That mix of lower risk and clearer costs is why many programme managers treat UK Cable Manufacturing and UK builds as strategic, not tactical.

A good shop updates route cards/build records the same shift a drawing changes so the operator on the line isn’t working to an obsolete rev, provides direct engineering access for sign‑offs, and holds pre‑agreed alternates plus small buffers for risk parts so low‑value items never stop high‑value work.

Use a short checklist during supplier assessment and audit:

Request a secure facility audit, see where we assemble and test, and review site controls and documentation. Prefer a fast start? Send us your drawings and our engineers will draft the test plan, the documentation pack, and a realistic lead time.

Need sector alignment (AS9100, ISO 13485, IATF 16949)? We’ll map requirements to your acceptance plan. Contact us

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.