This blog explores key safety standards in cable assembly design and manufacturing, highlights where projects commonly fall short and explains how partnering with a certified manufacturer like GEM Cable Solutions can help you stay ahead of regulatory risks.

Common Compliance Gaps That Risk Your Project

Procurement teams and engineers are often confident their cable assemblies are compliant until they’re not. Delays, safety issues, and rejected inspections often stem from overlooked details or assumptions during specification or sourcing. Common issues include:

- Insufficient material traceability – Lacking documentation on insulation ratings, conductor materials, or batch origins.

- Mismatched standards – Assemblies labelled “compliant” without understanding if they meet BS 7671, UL, or IPC/WHMA-A-620 standards.

- Over-reliance on self-certification – No third-party validation or full documentation, which leads to challenges during audits.

- Missing production-level testing – Relying on supplier assurances instead of verified performance under stress and environmental conditions.

These gaps can delay system commissioning and increase long-term operational risks., particularly in regulated environments like aerospace, defence, and rail.

Partnering with a manufacturer who builds compliance into every step can help eliminate these risks from the outset.

Understanding the root causes of non-compliance is only half the equation. To avoid them, you need to know which standards apply to your application.

Key Electrical Safety Standards

BS 7671 (IET Wiring Regulations)

BS 7671 is the UK standard for electrical installation. Often referred to as the IET Wiring Regulations, it outlines how electrical systems must be designed, installed, and tested.

This standard primarily applies to fixed installations, but cable assemblies for these environments must still align with its requirements, including current-carrying capacity, insulation, protection, and conductor types.

IEC Standards

International Electrotechnical Commission (IEC) standards are used globally, particularly for export-oriented manufacturers and systems integrators.

Relevant standards include:

- IEC 60204-1: Covers electrical equipment for machinery, including safety, wiring practices, and labelling.

- IEC 60320: Regulates appliance couplers, ensuring safe connections for plug-and-play assemblies.

These standards are essential for industrial cable assemblies installed in automated machinery or exported equipment.

UL Standards

For cable assemblies entering the US market, Underwriters Laboratories (UL) standards are key. Common standards include:

- UL 62: Flexible cords and cables

- UL 758: Appliance wiring material

- UL 817: Power supply cords and sets

Meeting these ensures that assemblies are accepted in North American markets and meet stringent safety requirements.

IPC/WHMA-A-620

This global standard defines the acceptability of cable and wire harness assemblies. It outlines how assemblies should be constructed, soldered, crimped, labelled, and tested.

If your cable assembly is used in aerospace, defence, or telecoms, IPC/WHMA-A-620 compliance isn’t optional. It’s often written into procurement contracts and supplier requirements.

Best Practices for Compliance

1. Material Selection

Start with certified, traceable materials. Conductors should meet conductivity and strength requirements. Insulation must handle temperature, chemicals, and mechanical stress. Shielding and jacketing must protect against EMI and moisture.

At GEM Cable Solutions, all materials are sourced from trusted suppliers and inspected before use.

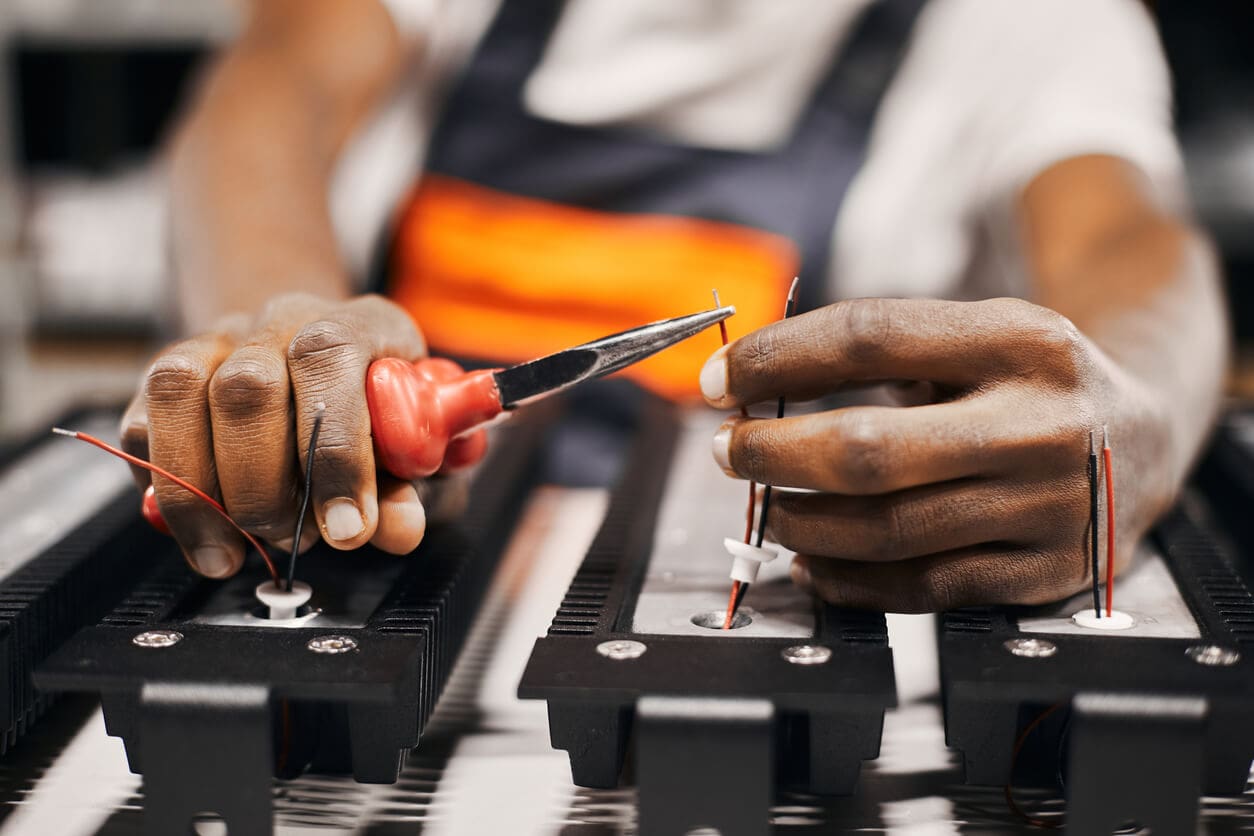

2. Rigorous Testing

Teams must go beyond visual checks. Run every cable assembly through:

- Continuity and insulation resistance testing

- High-pot (dielectric withstand) testing

- Environmental stress testing (temperature, vibration, moisture)

- Pull and flex testing for mechanical durability

GEM Cable Solutions performs full in-house testing to ensure each cable assembly meets compliance standards and delivers first-time accuracy.

3. Documented Traceability

For industries like aerospace or defence, traceability is not negotiable. Each assembly should come with a manufacturing record, including:

- Material batch numbers

- Test results

- Assembly procedures

- Quality control sign-offs

These records ensure your cable assembly meets required standards and protect your business during inspections or audits.

4. Engineering Oversight

Our engineers begin every project with compliance in mind. They review client specifications and apply all relevant standards from the start. This approach cuts error, improves safety, and simplifies your internal approval process.

GEM Cable Solutions: Built for Compliance

At GEM Cable Solutions, we build cable assemblies designed to meet exacting regulatory and industry requirements in the most demanding sectors.

- ISO 9001 & AS9100 certified: Meeting quality standards for aerospace and industrial manufacturing

- MIL-SPEC capable: For defence and mission-critical applications

- IPC/WHMA-A-620 trained technicians: Ensuring global assembly acceptability

- Custom documentation & test reporting: Ready for audits, approvals, and defence procurement

We work with clients across the UK and US to support compliance with local regulations and global export requirements.

Get it Right the First Time

Still have questions? Here are some of the most common concerns our clients bring to us.

Mistakes in compliance aren’t just technical issues. They cost time, budget, and reputation. Working with a proven cable assembly partner can remove uncertainty from the sourcing process. GEM Cable Solutions helps you meet compliance targets, pass inspections, and keep your projects on track from day one.

Contact us today to see how we help prevent compliance issues before they arise with tested, traceable, and industry-approved cable assembly solutions.

Frequently Asked Questions We Receive

What industries benefit most from compliant cable assemblies?

Any highly regulated industry like aerospace, defence, rail, industrial automation, or telecoms needs certified, traceable assemblies to meet both internal and legal compliance demands.

Can GEM Cable Solutions manufacture assemblies to UL or MIL-SPEC standards?

Yes. We meet a wide range of international standards including UL, MIL-SPEC, IPC/WHMA-A-620, ISO 9001 and AS9100. Our capabilities ensure acceptance in UK, US, and global markets.

How fast can GEM deliver compliant assemblies?

Lead times vary by complexity, but our in-house production and engineering teams are structured for agile delivery. We work closely with you to meet your timelines without compromising quality.

What documentation will I receive with my cable assemblies?

We provide full test reports, material traceability documents, and compliance records tailored to your project and audit requirements.

What if I’m unsure which standard applies to my assembly?

Our engineering team works with you from the start to select the correct cable assembly specifications and standards, helping you avoid rework or costly compliance setbacks.

Explore our product range to see how we support safety and performance from the ground up.