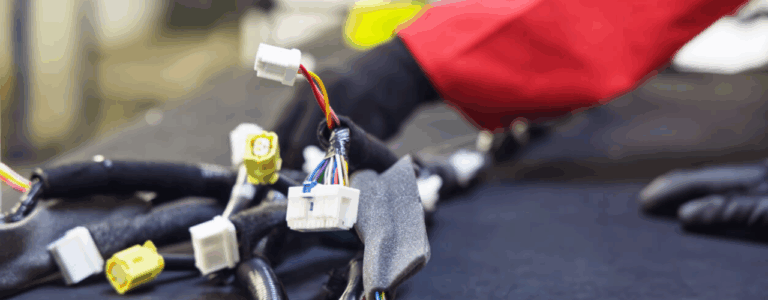

Are Obsolete Connectors Stalling Refurb Work for Today’s Wire Harness Manufacturers?

Refurbishment and life-extension projects should be straightforward on paper. You have proven equipment in the...

Read MoreAutomation is driving revolution across all industries, powered by the concept of Industry 4.0 and the Industrial Internet of Things. You don’t have to look far to find evidence of this in action, whether that’s smart factories, the increasing use of robotics or process control and automotive assembly. Enabling the next wave of industrial automation are the ethernet-based networks and architectures that have the ability not just to withstand harsh environments but to ensure the data communication that is so vital to Industry 4.0.

There is no doubt that the increase in digital technology has been driving the move away from traditional fieldbus protocols and towards ethernet-based networks. In comparison to the more old school fieldbus, ethernet-based networks have a lot of advantages that are crucial for automation environments. For example, they provide a high speed solution that is low jitter and very straightforward to implement where existing networks are concerned. When it comes to delivering on the goals of the automation environment – greater safety, more precise assembly and real time communication – it’s ethernet-based solutions that have the potential to meet expectations.

Classic ethernet would not have been an option to support the automation environments of today but plenty of evolution has taken place in recent years, including changes, such as Time Sensitive Networking. This has been necessary to overcome problems such as an inability to reserve bandwidth or guarantee latency between nodes. However, support for changes such as Time Sensitive Networking requires more adjustment, including switching hardware to ethernet nodes. Currently, in the US CIP networks still have a dominant position in the market – but that is likely to change. Ethernet/IP is the fastest-expanding technology and there are clear shifts happening in the US towards it. PROFINET, Ethernet/IP and EtherCAT, remain the most popular Ethernet-based networking solutions in Europe.

Single pair ethernet is a cable configuration where a pair of twisted wires is used to transmit data. It has a number of key benefits when compared to classic ethernet and has been largely responsible for accelerating the automation of many industrial environments. For example, an SPE has smaller cables, thinner bending radii as well as transmission rates of up to 1 Gb/s on a single pair. Because it’s compact it’s very useful for small systems and equipment and can be used to upgrade existing two-wire systems. It’s a prime example of the vital importance of cables in enabling ethernet-based networks to impact automation environments. Whether selecting SPE or another option, there are various considerations that need to be factored in when picking the best connector solution for industrial networks, including:

Connectivity solutions for industrial environments are vital to ensure that ethernet-based networks are able to continue to accelerate the way industrial automation is expanding.

Refurbishment and life-extension projects should be straightforward on paper. You have proven equipment in the...

Read More

Sustainability and ESG used to sit at the edge of technical projects. Today, they run...

Read More

Southern Manufacturing & Electronics 2026 brings the UK’s design and engineering community together under one...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.