What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance, communications relay, explosive ordnance disposal and logistics support.

All of these platforms depend on reliable power and data links. When wiring fails, the result goes beyond a nuisance fault. It can mean an aborted mission, a lost air vehicle or an unmanned asset that becomes unsafe to recover.

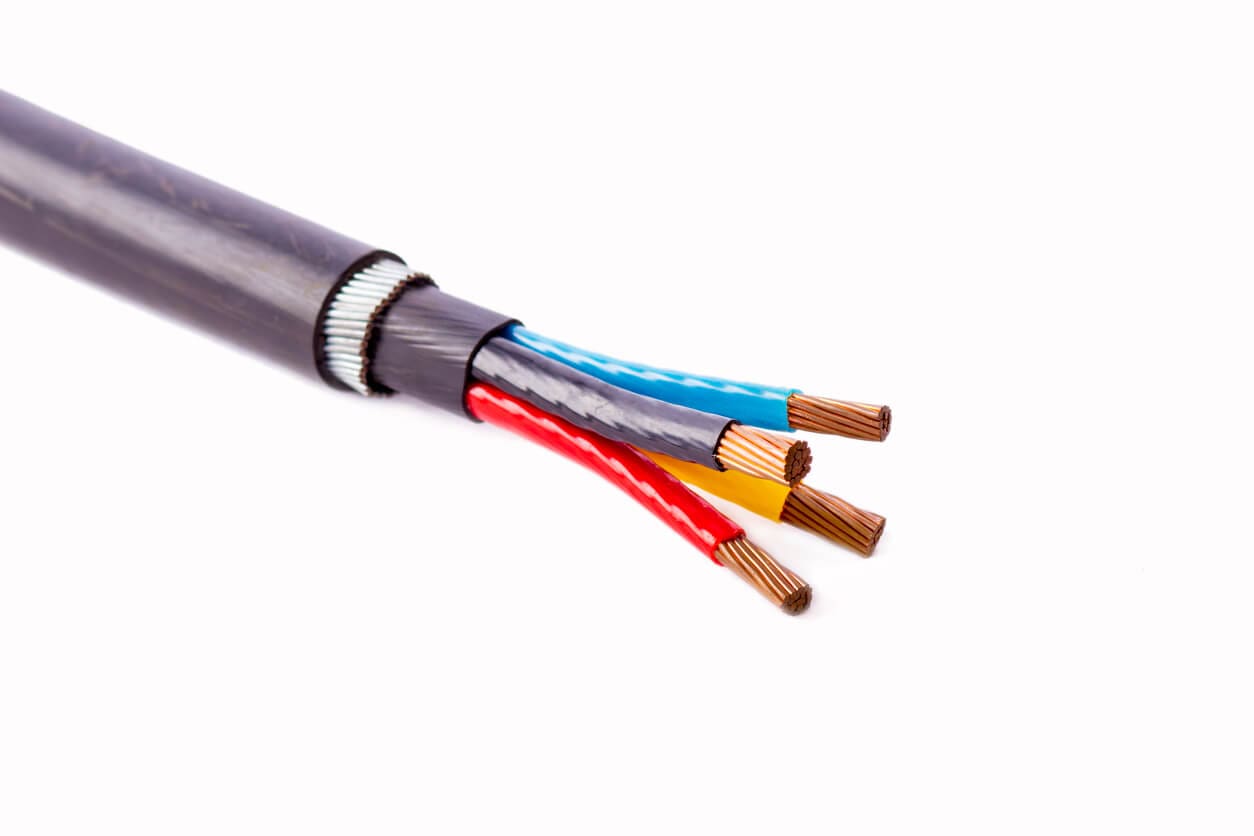

Many legacy platforms still carry mixed, commercial-grade wiring that was never designed for today’s environments or payloads. Moving to defence-standard (DEF STAN) cabling (often referred to in shorthand as DEF cable) gives programme teams a structured way to upgrade unmanned systems without redesigning every subsystem from scratch. If you sign off availability targets for unmanned fleets, these wiring decisions sit directly in your world.

Unmanned air, land and maritime platforms use a mix of looms, jumpers, tails and assemblies to move power and data between subsystems. DEF Stan cable assemblies sit in several critical paths:

Some runs sit hidden inside tight fuselages or hulls, while others cross masts, booms or undercarriages and are exposed to weather and mechanical damage. A DEF cable built and assembled to Defence Standard specifications gives designers predictable performance across both types of routing.

By specifying DEF Stan cable assemblies from the outset, programme teams can standardise on conductor sizes, insulation systems, screening options and jackets that match the platform’s role rather than relying on whatever commercial cable happened to be on the shelf during early prototyping. Those routes also generate many of the hard-to-find faults on unmanned platforms, so upgrading them to DEF Stan cable assemblies pushes issues into a controlled build and validation process.

UK military wiring standards do more than tell you which materials to use. They set expectations for how wiring is designed, built, tested and documented across the entire fleet.

In unmanned systems, that translates into several practical changes:

When a DEF cable comes from a manufacturer working to UK military wiring standards, platform engineers know that each assembly follows the same rules. That reduces the risk of “one-off” looms on individual airframes and helps supportability teams manage changes over the life of the programme. For programme managers, that means fewer wiring variants to control, and a clearer evidence trail when platforms go through acceptance, upgrades or audit.

Unmanned platforms concentrate energy and electronics into very small spaces. Battery bays, avionics compartments and sealed electronics pods have limited ventilation and can be difficult to access in a hurry.

Using flame retardant DEF cables in these zones reduces the risk that a wiring fault will escalate into a fire that damages the platform or nearby assets. Limited fire hazard constructions, often with low smoke zero halogen (LSZH) jackets, are designed to resist ignition and self-extinguish when exposed to flame. They also limit smoke and toxic output and maintain circuit integrity for as long as the design requires.

In a ship hangar, vehicle bay or forward operating location, this behaviour helps protect crews and other equipment when something goes wrong inside an unmanned asset. For battery-heavy UAVs and hybrid UGVs, it also supports safety cases around thermal runaway scenarios and emergency procedures.

By upgrading to flame retardant DEF cables in these compartments, programme teams reduce the consequences of internal faults without completely redesigning the bay layout. In business terms, that supports platform safety cases and helps protect availability targets when fleets operate from shared hangars or vehicle bays.

Not every cable on an unmanned system needs additional mechanical protection. Armour adds weight and increases bend radius. Used in the wrong place, it can create new routing problems.

Some routes genuinely need armoured defence wiring:

In these cases, an armoured DEF cable protects the conductors and screening from direct damage. Combined with correct clamping and strain relief, it reduces the chance that an otherwise minor knock will create an intermittent fault or open circuit that takes the platform out of service.

A balanced design still keeps lighter looms inside the structure and uses armoured defence wiring only in known risk areas. For programme and support teams, that means fewer wiring repairs, fewer unplanned returns to base and lower maintenance spend.

You see the difference between commercial wiring and DEF cable most clearly in testing. DEF cable quality testing does not stop at simple continuity checks.

For unmanned air, land and maritime platforms, a typical regime includes:

Because unmanned systems often operate beyond line of sight, these tests link directly to mission readiness and reduce the risk of wiring defects surfacing only as intermittent link loss, unexplained resets or failed self-tests.

Working with a manufacturer that treats DEF cable quality testing as standard cuts wiring-related surprises on the range or during deployment. It also means fewer test flights or trials lost to faults and more time spent proving capability.

Upgrading wiring in unmanned platforms is rarely as simple as swapping one cable for another. Programme teams, platform engineers and commercial leads need a partner who understands both the standards and the realities of constrained envelopes, legacy designs and evolving payloads.

GEM works with defence and security customers to design DEF Stan cable assemblies suitable for unmanned architectures and for use in new builds:

Partnering with GEM cable solutions for DEF wiring unit built and tested to UK military standards can give you a more predictable platform to work from and a single accountable supplier for design, build, testing and documentation.

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Motorsport teams chase marginal gains in every area of the car, yet many still treat...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.