What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

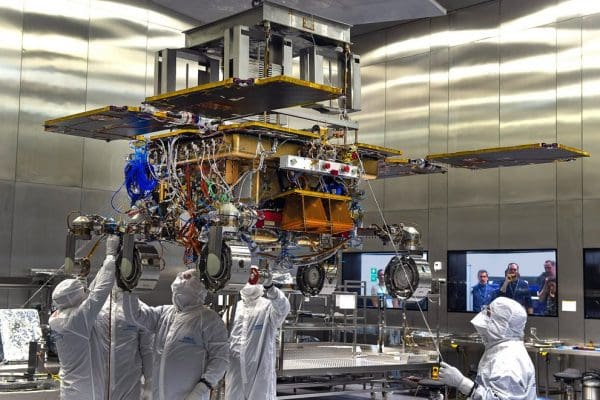

Most of you will know Airbus as the global leader in aeronautics, space etc and be very familiar with the work that this innovative behemoth does. Currently, Airbus employs some 134,000 people on a global basis and there is no doubt that the company is one of the most prominent in Europe when it comes to everything, from passenger airliners to transport and mission aircraft. Airbus successfully straddles both the civil and military aviation fields and has also become a pioneer when it comes to space. GEM Cable has worked with Airbus over many years and, in particular, when the global giant came to request help with a very specific project: the Mars Rover.

It’s part of a joint collaboration between the European and Russian space agencies focused on testing the technology required for a future mission to explore the surface of the planet Mars. Ultimately the goal for the collaborative efforts focused on Mars is to understand the geological environment and search for life on Mars. The Mars Rover project is key to this, as it’s a robotic vehicle that has the ability to drill up to two metres below the surface of the planet to look for signs of life, past and present.

When Airbus approached GEM Cable the company was looking for some specialist insight and support with the design, manufacture and testing of all the cabling for this pioneering project. This includes cable assemblies, harnesses and panels. Given GEM Cable’s range of skills and experience the partnership was a perfect fit for the Mars Rover Project. Not only have we worked extensively in the aerospace sector but also on a range of defence and satellite projects. GEM Cable has a wealth of experience in terms of providing bespoke support, which was vital for such an innovative and cutting edge project.

Our team is the only independent bespoke cable assembly manufacturer with Airbus approval and all designers and engineers have been trained to IPC-A-620 standard. With Airbus confidence in the business firmly established due to these high standards the team at GEM Cable went on to build bespoke harnesses, looms and panels, designed and tested to the highest standards, and delivered to a tight timeline. Our team was able to be responsive to the needs of this innovative project, including delivering on changes and modifications requested by Airbus at the last minute. Airbus noted the work that the team had put in, the agility that the business demonstrated and the very high standards that were met in the bespoke approach taken to supporting the Mars Rover Project.

When it comes to reliable cable assemblies and harnessing there is perhaps no environment more demanding than Mars. Gem Cable is incredibly proud to have supported Airbus in the Mars Rover Project and to continue to build a strong relationship as an approved supplier.

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.