What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

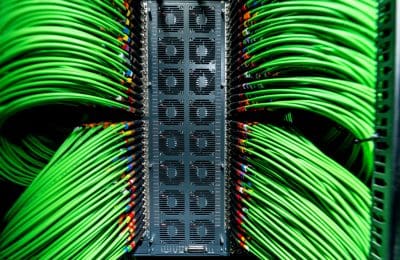

Cable assemblies are the unsung heroes behind many of the technologies we use daily, from the electronics in our homes to the machinery in large industrial plants. They form the foundation for efficient power transmission, data communication, and connectivity, ensuring that systems and devices operate seamlessly. Cable assembly manufacturers play a pivotal role in creating these critical components, and as industries evolve, their importance continues to grow.

In this blog, we’ll explore how cable assembly manufacturers contribute to the modern industrial landscape and the trends shaping their future.

Cable assemblies are essentially groups of wires, connectors, and other components that are bundled together to perform a specific function, such as transmitting power or data between devices. These assemblies can vary in complexity, from simple power cords to highly specialized systems used in advanced machinery, medical devices, and aerospace applications.

The key advantage of cable assemblies is their ability to simplify installation, reduce the risk of errors, and increase the overall efficiency of electrical systems. By customizing each assembly for a specific application, manufacturers can ensure a seamless and reliable connection that meets the precise needs of the industry.

For example, in the automotive industry, custom cable assemblies are used to connect various electrical systems within vehicles, such as sensors, lights, and navigation systems. In the aerospace industry, cable assemblies are crucial for ensuring that avionics and other critical systems function flawlessly during flight.

One of the most significant trends in the cable assembly industry is the increasing demand for customized solutions. As technology advances and industries become more specialized, the need for tailor-made cable assemblies grows.

Cable assembly manufacturers are responding to this demand by offering bespoke solutions designed to meet the specific requirements of their clients. Whether it’s a unique connector, a particular wire material, or an assembly built to withstand extreme temperatures or environments, manufacturers are continuously innovating to create assemblies that fit a wide range of applications.

For example, in the medical field, cable assemblies must meet strict regulatory standards and be designed for reliability and safety. This has led to an increased need for manufacturers to produce assemblies that are not only customized for functionality but also meet the rigorous safety and durability standards required for medical devices.

The future of cable assembly manufacturing is closely tied to the evolution of technology. As industries such as telecommunications, renewable energy, and electric vehicles continue to grow, the complexity of cable assemblies is increasing.

For instance, the rise of electric vehicles (EVs) has led to a surge in demand for specialized cable assemblies that can handle higher voltages and currents. These assemblies must be durable, lightweight, and able to meet safety standards, all while ensuring reliable performance in the demanding environment of electric vehicles.

Similarly, the rapid expansion of 5G networks and the increasing need for high-speed data transmission is driving the development of specialized cable assemblies for telecommunications. Cable assembly manufacturers are continuously developing new technologies to support higher frequencies, faster data transfer speeds, and better signal integrity, which are essential for the successful rollout of 5G and other next-generation networks.

As industries and consumers become more eco-conscious, sustainability has become a key priority for cable assembly manufacturers. The manufacturing of cable assemblies can result in significant waste, and companies are increasingly focused on reducing their environmental impact.

Many cable assembly manufacturers are investing in sustainable practices, such as using recyclable materials for wires and connectors, minimizing energy usage during production, and reducing waste in the manufacturing process. Additionally, there is a growing trend towards designing cable assemblies that are more energy-efficient, helping to reduce the carbon footprint of end-user systems.

The automotive industry, in particular, is driving the demand for sustainable cable assemblies, as automakers work towards producing greener, more energy-efficient vehicles. Cable assemblies that contribute to reducing the overall energy consumption of electric vehicles or supporting renewable energy systems are a growing area of focus for manufacturers.

Given the critical role that cable assemblies play in so many industries, quality control is essential in ensuring their reliability and performance. A failure in a cable assembly can have serious consequences, especially in sectors like healthcare, aerospace, or automotive, where safety is paramount.

Cable assembly manufacturers must implement rigorous testing procedures to ensure that each assembly meets the required standards and performs reliably over time. These tests may include electrical testing, environmental testing (to simulate harsh conditions), and mechanical stress testing to ensure that cables and connectors remain intact and functional under pressure.

Manufacturers are increasingly adopting automated testing processes, which help improve the accuracy and efficiency of quality control, while also minimizing human error. With advancements in technology, manufacturers can now test assemblies faster and more comprehensively, providing greater peace of mind for clients and end-users.

Looking ahead, the future of cable assembly manufacturing in the UK is full of opportunities, particularly as industries continue to embrace new technologies and sustainability practices.

Some of the most notable trends in the future of cable assembly manufacturing include:

Cable assembly manufacturers are integral to the functioning of countless industries, providing the reliable connections that power everything from data centers to electric vehicles. As technology evolves and industries become more specialized, the demand for customized, high-performance cable assemblies will continue to rise.

To stay competitive, cable assembly manufacturers will need to embrace innovation, sustainability, and advanced manufacturing technologies, ensuring they can meet the increasingly complex needs of their customers. With these changes, the future of cable assembly manufacturing looks promising, offering new opportunities for growth and innovation in a rapidly evolving world.

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.