Are tighter offshore maintenance windows raising the stakes for marine cable suppliers?

Offshore maintenance windows define limited periods when vessels, personnel, and equipment can access offshore assets...

Read More

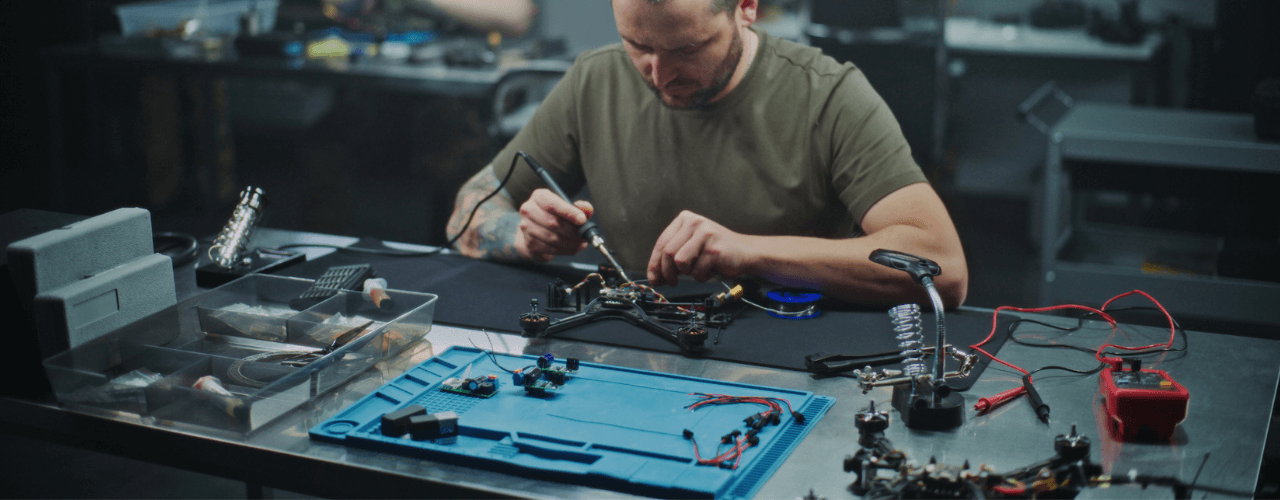

When a product team builds a prototype, cable assemblies are hardly finished on the first attempt. A connector changes, a cable length needs adjusting, or a routing decision made in CAD does not work in the physical build. Testing pauses while the assembly is corrected.

As prototyping speeds up, this stop–start pattern happens more often. Teams run more iterations in shorter windows, often before specifications have fully settled. In that environment, cable assemblies either keep pace with design change or become the point where progress slows.

This is what has shifted expectations of cable assembly manufacturers during prototype builds. Delays rarely come from manufacturing capacity alone. They usually appear when revisions, documentation, and build intent fall out of sync, making process control and repeatability as important as speed.

Rapid prototyping places cable assemblies in a different role than they hold in stable production programmes. Assemblies must adapt repeatedly as form factors, routing, and interfaces evolve between builds. This is mainly true where specialist connectors or terminations are involved, such as those supported within GEM’s connectors and crimp tools range.

When iteration cycles accelerate, even small delays in clarification or revision control can interrupt testing schedules. Cable assemblies become a constraint when they sit at the intersection of design change and physical build. This is where assumptions surface quickly and consume valuable development time.

Product teams need cable assembly manufacturers that can keep pace with frequent design changes without losing clarity or build consistency between iterations.

During prototype phases, teams need manufacturers that can work effectively when specifications change and information remains incomplete. Expectations shift away from optimisation and scale, and towards clear handling of revisions and consistent short-run builds.

In practice, this means supporting frequent design changes without introducing confusion between iterations and maintaining clear records of revisions and build intent so assemblies reflect the latest specification without requiring rework. The ability to produce small quantities consistently, while tracking changes accurately, often matters more than nominal turnaround speed alone. This is particularly relevant for teams developing early-stage assemblies similar to those used in sectors such as robotics and medical, where prototype builds evolve rapidly.

Cable assembly manufacturers struggle most during rapid prototyping cycles when revision control, documentation, and change communication cannot keep up with iteration speed.

Rapid prototyping exposes weaknesses that stable production environments often conceal, and informal processes start to break down. When revision cycles compress, manufacturers that rely on rigid processes or informal change handling can struggle to keep builds aligned with current designs.

Common issues include unclear ownership of revisions and assumptions carried forward between prototype versions, as well as documentation that does not clearly reflect what has changed between builds. These problems often surface during testing, when teams expect to validate designs rather than revisit basic build assumptions. Teams discover that assemblies reflect outdated specifications or inconsistent interpretations of design updates.

When prototype cycles accelerate, teams benefit from pausing to sense-check whether current cable assembly processes genuinely support rapid iteration. Reviewing how revisions are handled and how build intent is documented can help product teams identify where friction may be slowing development before it becomes visible during testing.

If you want to discuss specific prototype build requirements or sense-check whether your current approach supports rapid iteration, you can start a technical conversation via GEM Cable’s contact page.

Speed matters in rapid prototyping. Fast turnaround without disciplined change control often introduces delays. An assembly delivered quickly but built to an outdated or incomplete specification can interrupt testing and force additional clarification or rebuilds.

For prototype programmes, teams need confidence that each iteration accurately reflects the current design state. Turnaround time only supports progress when it is matched by clear revision tracking and predictable build execution across successive prototype versions.

You can assess a cable assembly manufacturer’s suitability for rapid prototyping by examining how they manage revisions and short-run repeatability when uncertainty remains between builds.

Product teams must use a different lens when they assess a cable assembly manufacturer for prototype work than when they evaluate long-term production partners. That lens should focus on how manufacturers handle change, ambiguity, and short-run repeatability.

Useful questions include how revisions are tracked and communicated between builds, how assumptions are validated when specifications are incomplete, and how teams maintain consistency across small quantities. Understanding how a manufacturer supports frequent iteration provides clearer insight than focusing on quoted lead times alone.

Prototype-ready cable assembly support combines technical capability with processes that accommodate ongoing change. This prevents iteration from stalling between builds. In practice, this is the level of support provided through GEM Cable’s bespoke cable assembly services, where short-run builds, revision control, and repeatability are treated as part of the development process rather than a handover point. This includes clear revision control, structured communication around design updates, and the ability to repeat builds reliably as specifications evolve, supported by controlled processes and testing approaches aligned with GEM Cable’s quality standards.

In practice, this approach helps product teams move through prototype cycles with fewer interruptions, reduced rework, and clearer alignment between design intent and physical builds. When cable assembly support aligns with rapid prototyping demands, development teams focus on testing and refinement instead of resolving preventable build issues.

As prototyping timelines compress, expectations of cable assembly manufacturers continue to shift in practical ways. This shift becomes visible long before production planning begins. Product teams increasingly require partners that can operate effectively within uncertainty and maintain clarity as designs evolve.

For teams developing new products under tight schedules, reviewing how cable assemblies are specified, revised, and built during prototype phases can help prevent avoidable delays. Aligning cable assembly support with the realities of rapid prototyping helps development cycles move forward without unnecessary friction.

For product teams working through rapid prototype builds, early discussion around cable assembly approach can reduce disruption later in the development cycle. A focused review of revision handling, documentation, and short-run repeatability during the prototype phase often helps clarify whether existing support is aligned with the pace of iteration required.

To discuss your prototype timeline or cable assembly challenges in more detail, visit the GEM Cable contact page to speak with the team.

Ready to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.