Unpainted Aluminium Enclosure 98mm x 64mm x 36mm

Read More

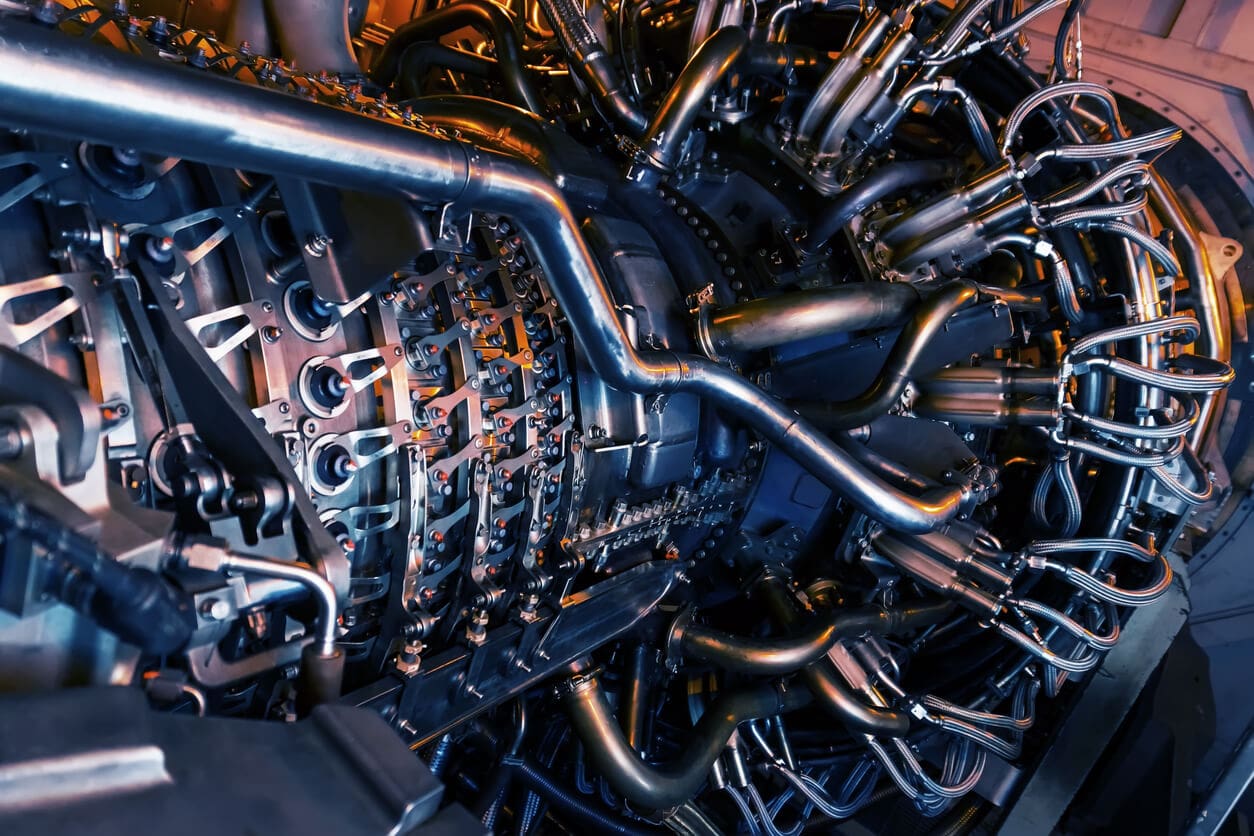

At GEM Cable Solutions, we specialise in delivering high-quality wire looms and cable harnesses tailored to meet the stringent requirements of the Defence industry. With a strong focus on precision and rapid turnaround times, we provide expertly engineered solutions for military, security, and aerospace applications across diverse environments.

All our products are manufactured entirely in the UK, within a Class 8 clean room environment, ensuring the highest standards of cleanliness and control during production. We have extensive experience in the manufacture of custom security and military cable assemblies, wiring looms, and bespoke wiring harnesses, all designed to meet the highest standards of performance and reliability.

Whether the requirement is a standard wire or cable or a highly specialized custom solution, GEM Cable Solutions is equipped to deliver.

As a trusted partner in the Defence sector, we are proud to hold JOSCAR accreditation, underscoring our commitment to quality, compliance, and transparency. We supply components and materials used in Mil-Spec wiring systems, sealed heatshrink systems, and military connector systems, with all Mil-Spec cable assemblies undergoing rigorous monitoring throughout production. This ensures full traceability, and certificates of conformity are provided with each shipment.

With expert knowledge of the specific requirements and quality systems necessary to support OEM military and defence contractors, we work closely with our clients to deliver tailored solutions. GEM Cable Solutions is dedicated to producing products that meet the most demanding specifications, providing exceptional attention to detail and the highest standards of excellence in every project.

Defence standard cable refers to cables manufactured in line with UK DEF STAN (Defence Standard) requirements. These cables are used in military vehicles, communication systems, radar, avionics, naval equipment, and other mission-critical defence applications where durability and reliability are essential.

“DEF cable” is a common industry shorthand for DEF STAN–approved cable. This can include power, signal, data, and multicore cables built to specific Defence Standards such as DEF STAN 61-12 or DEF STAN 02-526. These cables are engineered for harsh environments involving heat, vibration, and mechanical stress.

Mil-spec cable assemblies are cable systems manufactured to MIL-DTL, MIL-C, or other US military specifications. They include cables, connectors, and terminations designed to guarantee performance under shock, vibration, moisture, and extreme temperatures.

Defence standard cables meet strict performance and safety criteria that commercial cables cannot match. They maintain stable power, signal, and data transmission under demanding conditions, reducing the risk of failure in field operations and high-risk environments.

Yes. Many defence standard cables (such as DEF STAN 61-12 series) are widely used in aerospace systems for their heat resistance, mechanical strength, and proven reliability. They are suitable for aircraft wiring, avionics, communications, and structural monitoring systems.

Selection depends on voltage rating, insulation type, temperature range, environmental exposure, EMC requirements, and the specific DEF STAN specification. A specialist cable manufacturer or assembler can advise based on your system requirements and compliance standards.

Yes. Defence standard cables can be supplied cut to length, pre-terminated, or built into complete harnesses or looms. Custom configurations are common in vehicle wiring, aerospace assemblies, and naval systems due to varied installation requirements.

Testing can include continuity, insulation resistance, high-pot/voltage withstand, vibration, shock, mechanical pull testing, environmental sealing (IP ratings), and compliance checks against the relevant MIL specification. This ensures assemblies perform reliably in military environments.

Service life depends on temperature, mechanical stress, and installation quality, but defence standard cables are engineered for long operational lifespans. Their higher-grade insulation, jacketing, and conductor materials outperform typical industrial alternatives in durability and reliability.