Why Custom Cable Assemblies are Non-Negotiable for Defence, Rail, and Marine

The wiring harness is a high-risk single point of failure in any complex system. If...

Read More

A million-pound robotic system glides into place, its arm extending with flawless precision. Then, it stops. A single point of failure such as frayed or fatigued cable assembly brings a multi-million-pound production line to a halt. This is the hidden cost of complacency. Project managers often focus on the robot’s impressive specs and treat the cabling as an afterthought; a generic component easily sourced from a catalogue. But in the hostile, dynamic environment of an automated warehouse, this is a critical mistake. The cable assembly is the robot’s nervous system, a crucial element for its longevity. If not engineered to endure, it will become the single point of failure that erodes your ROI. A reputable UK cable manufacturer will help you avoid this fate. The key to true system reliability lies in a custom-engineered solution from a specialist UK cable manufacturer.

A cable endures a relentless, three-dimensional assault in an automated warehouse. No off-the-shelf product can withstand this. This is the precise challenge that expert UK cable manufacturers are engineered to solve. We’ve designed a solution for this reality.

Ignoring any one of these factors creates a recipe for unscheduled downtime and expensive repairs.

We engineer a custom solution for the specific test your robot faces, a process that goes beyond simply providing a longer cable. Our design process, honed by our experience as a leading UK cable manufacturer, is a direct response to the problems we’ve seen on the factory floor.

We often talk about a cable’s price tag, but the real cost lies in its failure. The initial savings from a cheap, off-the-shelf cable are quickly wiped out by a domino effect of expenses. This is an important distinction that a professional UK cable manufacturer always emphasises. A single failure can lead to:

By investing in a custom cable assembly engineered for longevity, you prevent this domino effect. It’s the difference between a predictable, low total cost of ownership (TCO) and a system that constantly needs reactive and expensive attention.

An experienced engineer doesn’t wait for a problem to occur; they prevent it. That’s why we approach every project with a “pre-mortem” mindset. We work with your team to identify every potential point of failure before we build the cable to spec. This includes analysing the specific movements, speeds, and environmental factors your robot will face. We use our expertise to model stress points and predict how a cable will behave over millions of cycles. This proactive cable failure analysis allows us to select the optimal materials and design a structure that withstands the unique “torture test” of your application. This strategic, collaborative approach is the most cost-effective way to ensure long-term reliability and a predictable TCO. Only a forward-thinking UK cable manufacturer can provide this level of preventative expertise, which eliminates the reactive, costly maintenance that comes with off-the-shelf solutions.

Want to learn more about our process? Contact us to discuss your project’s unique challenges.

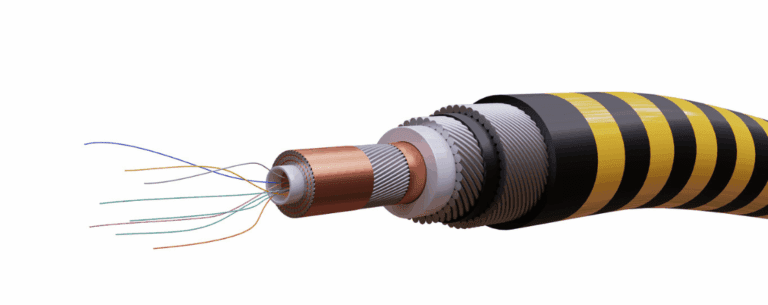

While this article focuses on the specific challenges of robotics in automated warehouses, our expertise in designing and manufacturing bespoke cable assemblies extends across a wide range of mission-critical sectors. Our solutions are trusted in aerospace, rail, broadcast, defence, motorsport, medical, nuclear, marine, telecom, and satellite applications, providing the same commitment to reliability and performance.

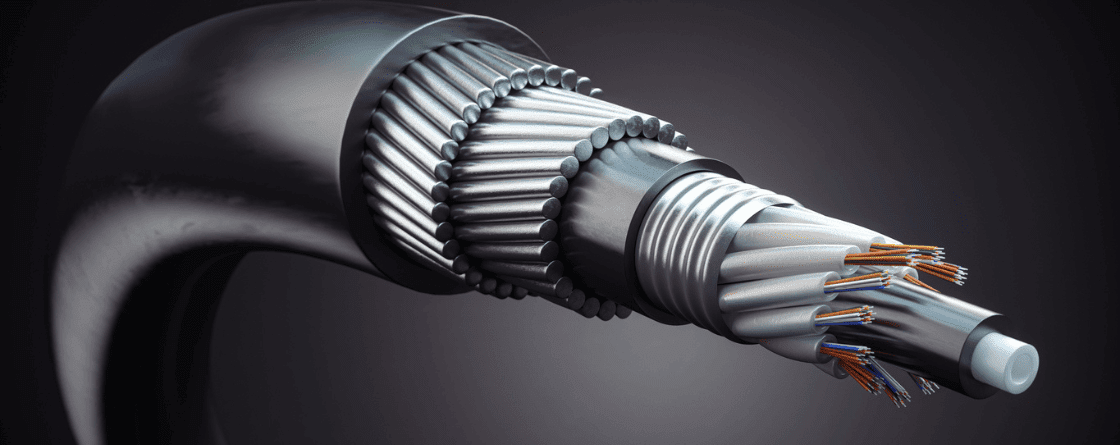

The demands of robotics are only increasing. This is why the role of a trusted UK cable manufacturer is evolving to meet these challenges. As a UK cable manufacturer, we constantly push the boundaries to provide solutions for next-gen automation. This includes highly integrated hybrid assemblies that combine power, data, and signal wires into a single unit. The push for smaller, lighter robots and collaborative robots (cobots) requires thinner, more flexible cables that don’t hinder delicate movements.

Choosing to work with a UK cable manufacturer means engaging with a strategic partner who understands the practical challenges you face. We offer an end-to-end partnership, from detailed requirements capture and rapid prototyping to rigorous testing and production. Our goal is to ensure your project’s success by providing a solution you can rely on, day in and day out.

With our custom solutions, you get:

Before your next project goes live, ask yourself a critical question: is your cable a part of the solution, or is it a ticking clock? Contact us today to discuss your project’s unique challenges and engineer a solution for peak performance.

The wiring harness is a high-risk single point of failure in any complex system. If...

Read More

Keeping complex systems online takes more than parts and datasheets. It takes cable assembly manufacturers...

Read More

The High Cost of a Single Component A single equipment failure brings a multi-million-pound project...

Read More

The Backbone of Global Connectivity Beneath the Waves Think about how often you rely on...

Read More

The Silent Network Powering the Digital World Did you know that over 99% of all...

Read More

In industrial and commercial sectors, cabling is the foundation of critical infrastructure, ensuring seamless power...

Read More

In high-stakes industries, failure is not an option. Defence, aerospace, telecommunications, and industrial applications demand...

Read More

Marine cables keep the world connected, forming the backbone of communication for industries such as...

Read More

Modern economic growth, business operations, and social connectivity all depend on seamless global communication in...

Read More

The UK is rapidly advancing its energy infrastructure, with a strong focus on offshore wind...

Read More

Now the world is more interconnected than ever before, but this global communication network wouldn’t...

Read More

Seamless digital connectivity has become second nature in our modern world, powering personal interactions, business...

Read More

In industries such as aerospace, defence, telecommunications, or medical devices, each sector has its own...

Read MoreIn the dynamic world of marine engineering, the International Marine Contractors Association (IMCA) plays a...

Read MoreSub marine cable technology is a fascinating piece of innovation that we so often take...

Read More

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.