What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

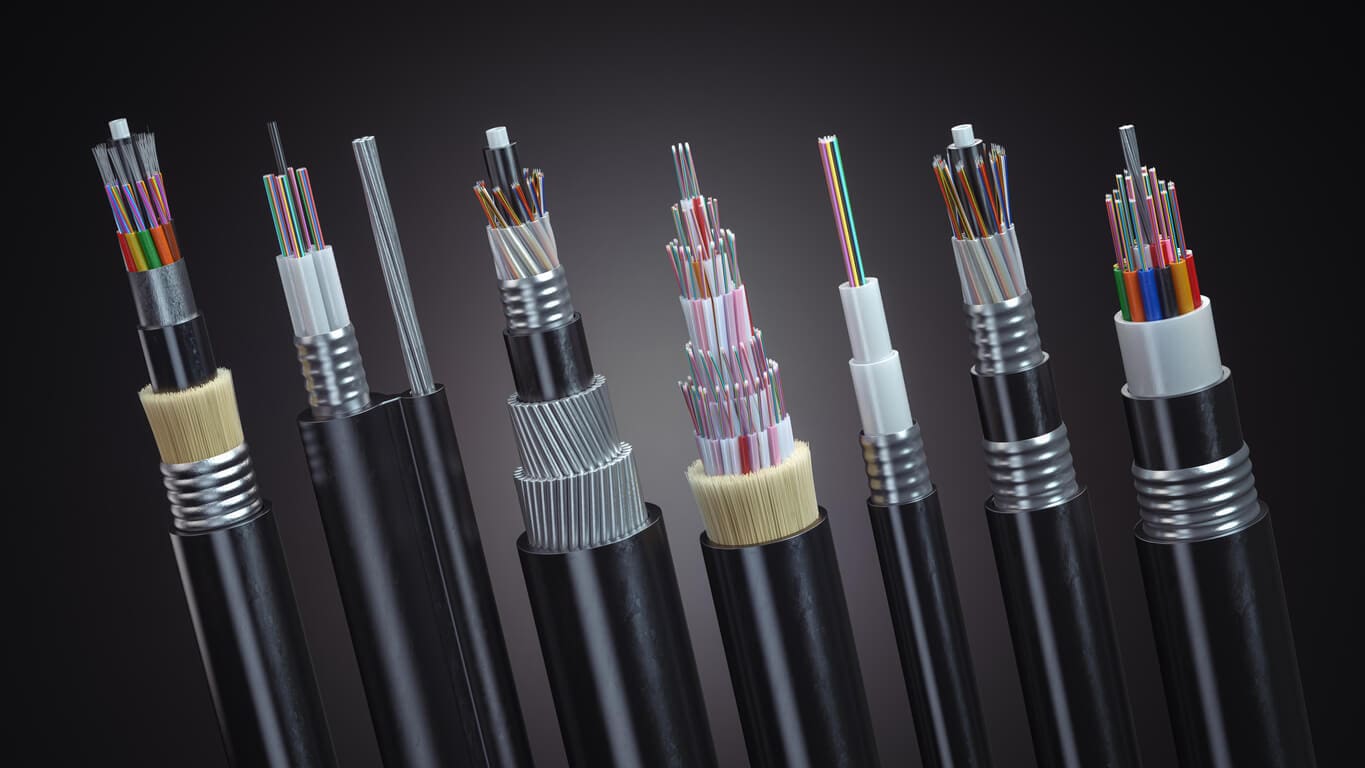

Fibre optic cable is the essential transport mechanism of the modern digital economy. It is the core of data centres, the lifeline of 5G networks, and the foundation of international connectivity via subsea systems. In high-stakes projects, how do you verify the integrity of the fibre optic cable assembly before it’s deployed? The answer lies not just in a test certificate, but in the supplier’s foundational process.

For engineers, procurement specialists, and project managers, choosing the right supplier is a strategic decision, not a simple procurement exercise. The market is saturated with options, yet few possess the technical depth and quality systems required for high-risk, mission-critical applications. This article outlines the absolute criteria you must evaluate when partnering with a specialist fibre optic cable manufacturer to ensure the longevity and performance of your most vital infrastructure.

The difference between a high-performance fibre assembly and one that fails in the field is measured in microns and decibels. If your supplier cannot demonstrate absolute mastery over the termination process, you are building in a failure point. A true expert in fibre assemblies must prove control over every step, backed by externally audited quality systems. A high calibre fibre optic cable manufacturer ensures quality is built in.

The single most common cause of fibre failure is poor termination and polishing. When assessing suppliers, look for those who can demonstrate their expertise in fibre optic solutions by controlling these core performance factors:

Certifications are proof that the manufacturer’s quality systems are externally audited, meeting rigorous, industry-specific requirements. Selecting an accredited fibre optic cable manufacturer is fundamental for risk management and de-risking your supply chain:

The ability to trace every component back to its source is vital for auditing, fault isolation, and compliance documentation in high-risk sectors. This uncompromising commitment to full provenance is what keeps your projects compliant and your operational risks low. This level of diligence defines a premium fibre optic cable manufacturer.

A top-tier fibre optic cable manufacturer must integrate the following requirements into their process to ensure a fully auditable and compliant supply chain:

Relying on distant supply lines introduces risk, delay, and uncertainty. Choosing UK-based fibre optic cable manufacturers offers significant strategic advantages in resilience and control. Partnering with the right fibre optic cable manufacturer based in the UK offers significant advantages.

UK-based manufacturing provides critical benefits that translate directly into lower project risk and greater agility:

A superior supplier partners with your engineering team to improve the drawing. Their expertise moves beyond simply building to a specification. The best fibre optic cable manufacturers act as engineering partners, and this value-add is often the difference between a compliant cable and an assembly that provides ultimate endurance and a significantly lower Total Cost of Ownership (TCO).

A fibre optic cable manufacturer’s Design for Manufacturability (DfM) expertise should provide the following value to your project:

The integrity of your fibre optic infrastructure is directly tied to the reliability of your cable assemblies. When you choose a partner, you are selecting an assurance of quality, process control, and performance. By demanding full traceability, exceptional technical standards (like AS9100 Rev D), and the resilience of a UK-based manufacturing partner, you secure the proven advantage of British engineering excellence, establishing a strategic relationship that safeguards your project’s long-term success.

The best fibre assembly partners offer a consultative approach, ensuring your cables are engineered to endure the specific demands of your operating environment. Don’t compromise on the central nervous system of your network.

Focus your attention on the test report, not the quote. The only true metric of quality in fibre optics is the verified, serialised data proving low loss and high reflection control.

Stop buying cables. Start investing in validated test process. As leading fibre optic cable manufacturers, Contact GEM Cable Solutions today to discuss your next-generation fibre project and guarantee the audited performance of your next assembly. You can also explore our full range of certified Fibre Optic Solutions.

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.