Is modular equipment driving new collaboration with cable harness manufacturers?

When teams design modular equipment, wiring problems tend to show up faster than expected. A...

Read More

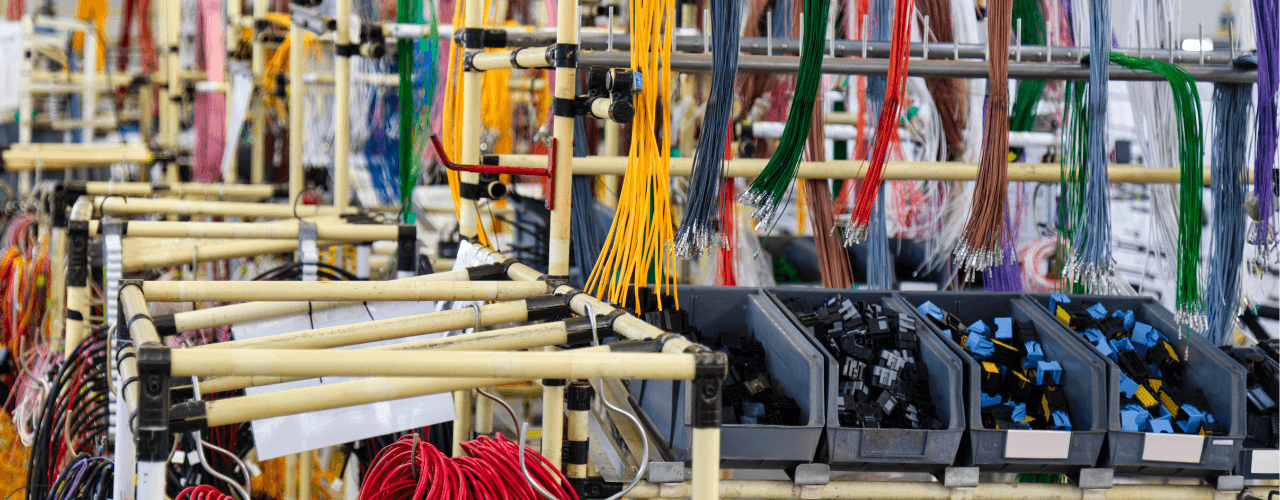

Engineers rarely treat a custom cable assembly as a flight-critical component. They should. A quality custom cable assembly executes a risk-assessed Design for Manufacturability (DfM) strategy, providing far greater value than a simple wiring bundle. In aerospace, medical technology, or high-speed data centres, off-the-shelf harnesses carry an inherent, unacceptable risk because they fail to meet the precise design parameters needed for decades of system longevity. A cable failure can halt production, cause a total mission abort, fail an audit, or compromise a life-critical system. Compliance begins at the design stage.

A specialist manufacturer’s mandate is to translate your operational demands into a singular, high-performance solution. This expertise spans critical sectors like Defence, Rail, and Marine, and requires a systematic assessment of three critical inputs that define the design requirements matrix: Electrical & Signal, Mechanical & Structural, and Environmental & Certification.

Understanding these factors allows engineers to properly vet a supplier and ensure the final custom cable assembly delivers its exact, non-negotiable purpose.

The primary factor addresses the electrical nature of the data the custom cable assembly must govern. The assembly must flawlessly regulate power and guarantee data transmission without degradation or noise.

The manufacturer selects and configs conductor types and twists to maintain signal integrity over distance. In high-speed data or high-frequency radio frequency (RF) applications, impedance matching is non-negotiable. If the cable’s characteristic impedance doesn’t perfectly match the system, it induces severe signal reflection and catastrophic data loss. The supplier mandates specific conductor materials and dielectric insulation to eliminate that risk.

The required amperage and operational voltage directly dictate the most fundamental component: conductor gauge. A mistake here causes overheating and thermal runaway.

No single shielding type serves every application. The surrounding electromagnetic environment (EMI/RFI) must drive the choice between a simple braid and a complex, multi-layered solution.

The location where engineers install a custom cable assembly and how it interacts with motion are critical determinants of its mechanical lifespan. A supplier must anticipate the physical demands on the cable, focusing on durability and seamless integration.

In dynamic applications, such as robotics, automated machinery, or heavy plant equipment, the cable is constantly flexing, bending, and twisting. This causes premature, catastrophic flex failure in standard components.

In platforms where every millimetre and every gram is critical, such as aerospace systems or tight console integration, the manufacturer must scrutinise and minimise the overall harness bulk. This consolidation demands a true custom cable assembly approach.

The physical termination points (connectors) are where 90% of field failures originate, which demands absolute precision. A specialist manufacturer demonstrates capability through continuous investment in specific, calibrated tooling.

The design must incorporate the external atmosphere and the required regulatory compliance from day one. These factors primarily dictate the Bill of Materials (BOM) and the manufacturing documentation process.

Engine rooms, outdoor marine platforms, industrial processing areas, and vehicle assemblies expose custom cable assemblies to corrosive fluids, extreme temperatures, and abrasive wear. Generic jacket materials fail rapidly.

In enclosed public or high-occupancy spaces (e.g., passenger rail or naval vessels), fire safety drives the primary environmental and legal factor. You must protect occupants from toxic smoke.

The final design requires full documentation and auditability. Compliance standards influence the design phase through explicit requirements for component tracking and documentation.

The hallmark of a high-reliability supplier lies not only in following your blueprint but also in their ability to vet it. They use their DfM expertise to actively challenge the design brief, identify latent failure modes, and engineer them out before the cable ever leaves the bench. That is the final stage of risk mitigation that a high-performance custom cable assembly provides.

This article has laid out the three pillars of custom design such as Electrical, Mechanical, and Environmental but applying them in a high-compliance, high-risk environment demands the specialised tooling, certified operators, and deep material science expertise we bring to every Design for Manufacturability (DfM) review. Don’t simply hope your current specifications will hold up for decades.

Select a partner who has the tooling, material inventory, and technical depth to master all three design factors. This approach removes the burden of material and process selection from your engineering team and validates that your harness offers decades of service.

Need someone to help for your next project? Contact us today for a no obligation quote!

Ready to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.