Is modular equipment driving new collaboration with cable harness manufacturers?

When teams design modular equipment, wiring problems tend to show up faster than expected. A...

Read More

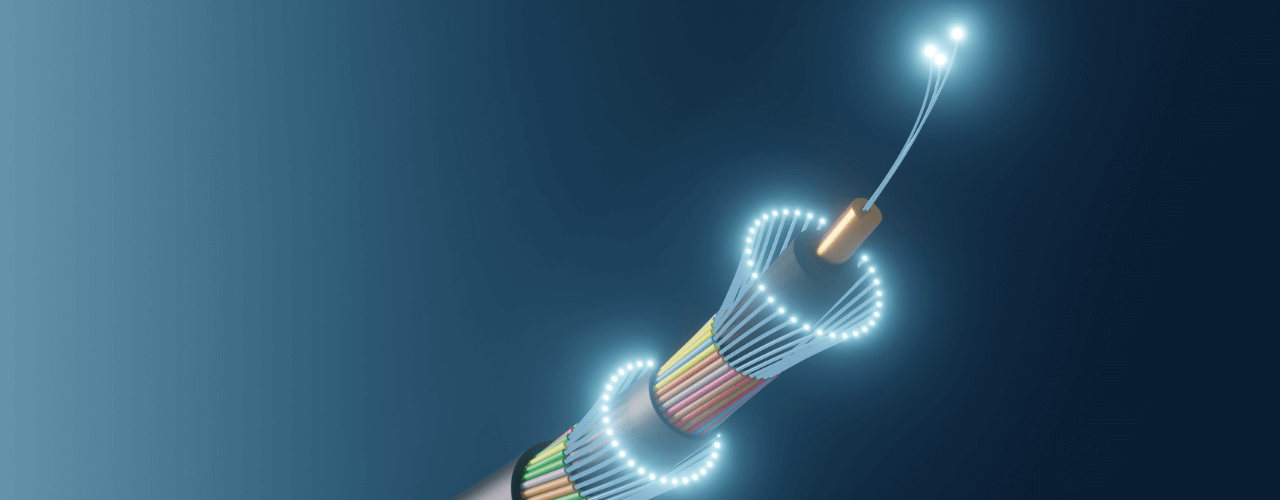

Offshore maintenance windows define limited periods when vessels, personnel, and equipment can access offshore assets to carry out repairs or replacement work. Once those windows close, work often stops for extended periods, depending on access and scheduling constraints.

That reality changes how teams handle cable supply. When access is constrained and timing cannot move, delays or errors directly affect asset availability and operating costs. This article looks at how tighter maintenance windows change what offshore operators should expect from a marine cable supplier, and how to make the right call under pressure. This is particularly relevant across offshore and marine environments such as those outlined in GEM Cable’s marine sector work.

Offshore maintenance windows make cable supply a risk decision because delays or errors cannot be recovered once access closes.

In offshore environments, teams no longer treat cable supply as a low-risk background procurement task. Once a maintenance window is fixed, every supporting component becomes part of a time-critical risk chain.

If a replacement cable or harness arrives late or is unsuitable for installation on arrival, the impact extends well beyond rework. It can mean missed access and extended downtime that forces maintenance campaigns to be rescheduled. Under these conditions, choosing a marine cable supplier depends less on availability and more on whether the supplier can perform reliably within immovable constraints. For procurement teams, this often means making supplier decisions faster than usual, with limited opportunity for re‑tendering or late clarification once work is mobilised.

In practical terms, offshore maintenance teams need suppliers that remove uncertainty when access windows are fixed and time cannot be recovered.

When maintenance windows tighten, expectations of a marine cable supplier change.

Offshore operators now prioritise suppliers that can:

These requirements sit at an operational level, not as optional extras. Under time pressure, the ability to act decisively and correctly often matters more than catalogue breadth or nominal lead times.

For offshore teams working within fixed maintenance windows, it can be useful to sense-check whether current cable designs and supply assumptions genuinely support install-ready delivery. Reviewing how assemblies are specified, built, and documented is particularly important where bespoke cable assemblies or integrated boxes, panels, and looms are involved. Doing so can help reduce late-stage issues once access is secured.

Marine cable suppliers often struggle under offshore time pressure when their internal processes cannot support fast clarification or consistent right-first-time delivery.

Common failure points include slow clarification cycles when information is incomplete and documentation that does not support rapid replacement or repair, particularly where cables interface with pre-built panels, looms, or enclosures such as boxes, panels, and looms. In practice, teams encounter these issues when assets are already offline and tolerance for delay disappears.

Speed matters during offshore maintenance, but it does not solve the problem on its own.

A cable that arrives quickly but requires modification or clarification on site can disrupt work more than a cable that takes slightly longer to produce and installs correctly first time. Under fixed maintenance windows, errors consume access time that cannot be recovered.

For offshore operators, the real requirement is confidence that supplied cables will install correctly and perform as expected without additional intervention. Fast turnaround only adds value when it is matched by accuracy and installation readiness.

You can assess a marine cable supplier’s ability to perform under offshore time pressure by testing how they handle unplanned work, documentation access, and compressed decision timelines.

When maintenance windows are fixed, supplier evaluation needs to be practical and direct, without relying on assumptions. Useful questions include:

These questions help shift the focus from promises to performance, and from nominal lead times to real operational readiness.

A marine cable supplier suited to offshore maintenance work combines technical capability with operational depth built through repeated exposure to time-critical work.

In practice, this means early clarification, disciplined manufacturing, accurate documentation, and the ability to deliver install-ready assemblies within fixed windows, supported by controlled production and testing processes such as those outlined in GEM Cable’s quality standards. It also means understanding that offshore maintenance is not forgiving of error, and that supplier performance is measured in time saved or lost on site.

Suppliers that operate this way reduce uncertainty during maintenance campaigns and help offshore teams complete work within the available access window.

Tighter offshore maintenance windows have raised the stakes for marine cable supply. Time pressure has turned supplier choice into a risk decision, where responsiveness and operational readiness matter as much as delivery speed.

If you are planning offshore maintenance work and need confidence that cable supply will not constrain your schedule, it is worth reviewing supplier assumptions early. GEM Cable works with offshore operators, engineers, and procurement teams to assess cable requirements in the context of real maintenance conditions and reduce risk when access time is limited. Contact us today!

Ready to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.