Are tighter offshore maintenance windows raising the stakes for marine cable suppliers?

Offshore maintenance windows define limited periods when vessels, personnel, and equipment can access offshore assets...

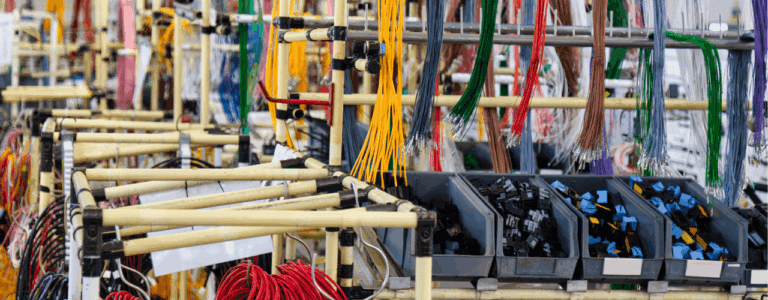

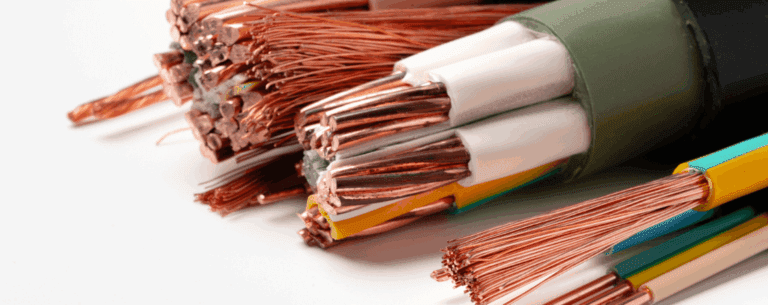

Read MoreWhile electrical safety standards are crucial, they’re only half the story. The physical workmanship of a wire harness assembly is just as critical for long-term reliability. This is where the IPC/WHMA-A-620 standard becomes our rulebook for excellence. As a global benchmark for cable harness manufacturing, IPC-A-620 defines the acceptance criteria for a perfect solder joint and a flawless crimp. This level of detail is vital in industries like military and aerospace cabling, where a single loose connection could have catastrophic consequences. Following these workmanship standards sets us apart. It’s a commitment to quality that goes far beyond a simple pass/fail electrical test.

In the global marketplace, we often see clients confused by the different certification logos. CE marking is a self-declaration of conformity for the European market. From our perspective, the manufacturer attests that their product meets all applicable directives. UL certification, in contrast, requires an independent, third-party testing process for the North American market. UL’s rigorous testing and follow-up services give clients a stronger guarantee. Distributors and end-users often require this non-negotiable. Understanding this distinction is essential for any cable manufacturing partner aiming for global reach.

External certifications provide a baseline, but the true expertise is what is done in internal facilities. Robust in-house testing and verification process ensures that every assembly will perform reliably in its intended environment.

This proactive approach to cable assembly verification is how manufacturers guarantee the longevity of your product, giving you peace of mind.

The sheer volume and complexity of these regulations can be a minefield. That’s where we come in. We build cables and partner with you to navigate the regulatory landscape. An experienced manufacturer is proactive, and that includes:

By offloading this complex task to a trusted partner, you can focus on your core business, confident that your product is safe, compliant, and ready for market.

Mastering the complex web of British and international standards is fundamental to modern cable manufacturing. These regulations are not obstacles, but essential safeguards that ensure the quality and reliability of your products and, ultimately, your safety. When you’re sitting in a project review meeting, you want to avoid a cable failure. By choosing a partner with true practical expertise, you’re investing in your project’s longevity and success.

Don’t let a compliance issue derail your next launch. Let’s discuss your project’s compliance needs and build a foundation for success. Schedule a call with our experts today.

Offshore maintenance windows define limited periods when vessels, personnel, and equipment can access offshore assets...

Read More

Electrical enclosures are getting smaller. Control cabinets, panels, and equipment housings now have less space...

Read More

Refurbishment and life-extension projects should be straightforward on paper. You have proven equipment in the...

Read More

Sustainability and ESG used to sit at the edge of technical projects. Today, they run...

Read More

Southern Manufacturing & Electronics 2026 brings the UK’s design and engineering community together under one...

Read More

Engineers rarely treat a custom cable assembly as a flight-critical component. They should. A quality...

Read More

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read More

Motorsport teams chase marginal gains in every area of the car, yet many still treat...

Read More

The wiring harness is a high-risk single point of failure in any complex system. If...

Read More

The wiring harness is the highest risk, lowest profile element in flight-critical infrastructure. When your...

Read More

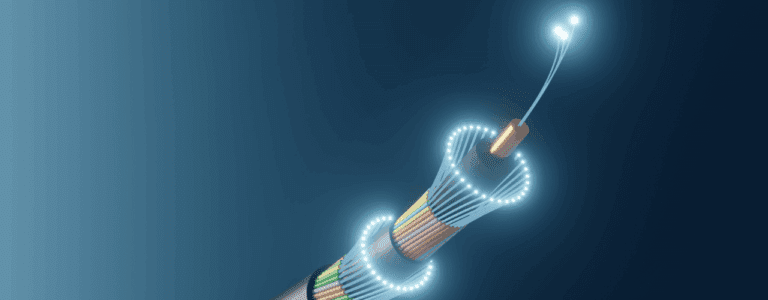

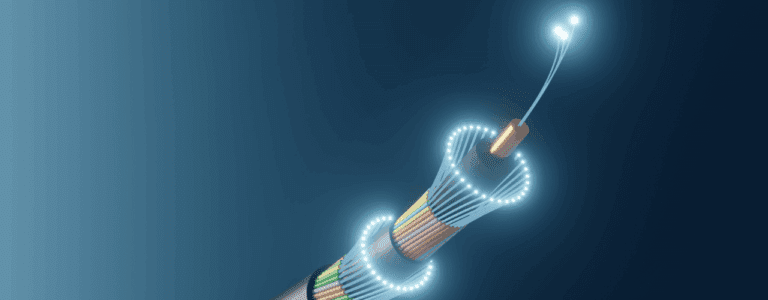

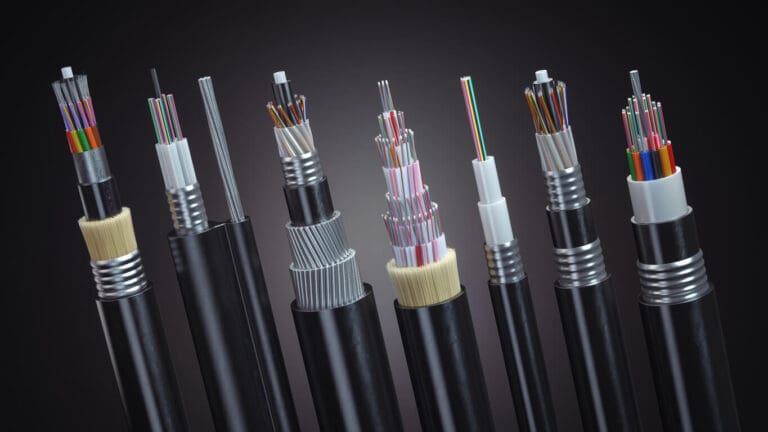

Fibre optic cable is the essential transport mechanism of the modern digital economy. It is...

Read More

Keeping complex systems online takes more than parts and datasheets. It takes cable assembly manufacturers...

Read More

Keeping critical infrastructure online and mission systems ready needs more than components. It requires domestic...

Read More

Offshore maintenance windows define limited periods when vessels, personnel, and equipment can access offshore assets...

Read More

Electrical enclosures are getting smaller. Control cabinets, panels, and equipment housings now have less space...

Read More

Refurbishment and life-extension projects should be straightforward on paper. You have proven equipment in the...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.