What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

A single equipment failure brings a multi-million-pound project to its knees. The cause? A seemingly minor detail: a non-marine grade cable jacket that succumbed to salt corrosion. The consequences, however, are anything but minor. They include millions in lost revenue from up to 60 days of operational disruption, plus the immense cost of emergency maintenance and specialised repair vessels.

In the offshore sector, cable reliability issues account for over 80% of insurance claims. This is why investing in durable marine cables is a necessity. As a marine engineer or offshore project manager, you know this risk is both real and substantial. Your choice of cabling is a strategic decision, not merely a technical specification, because it directly impacts operational resilience and a project’s long-term profitability. Purpose-built marine cables from the best UK cable manufacturers could have avoided all these problems.

The open ocean is a beautiful but unforgiving place, and for standard industrial cables, it is a graveyard. Three primary culprits relentlessly attack cable integrity: corrosion, UV degradation, and thermal and mechanical stress. The combination of saltwater and constant moisture, along with air, creates a highly corrosive environment where standard copper conductors quickly oxidise, leading to increased resistance, overheating, and eventual failure. UV radiation in the water column affects even submerged cables, breaking down the sheathing and creating a pathway for water ingress that accelerates corrosion. Finally, subsea cables must endure a constant barrage of stress, from thermal expansion and contraction, as well as the physical strain of tidal forces and underwater currents. Standard materials cannot handle this dynamic and cyclical punishment, which leads to micro-fractures that eventually become major failure points.

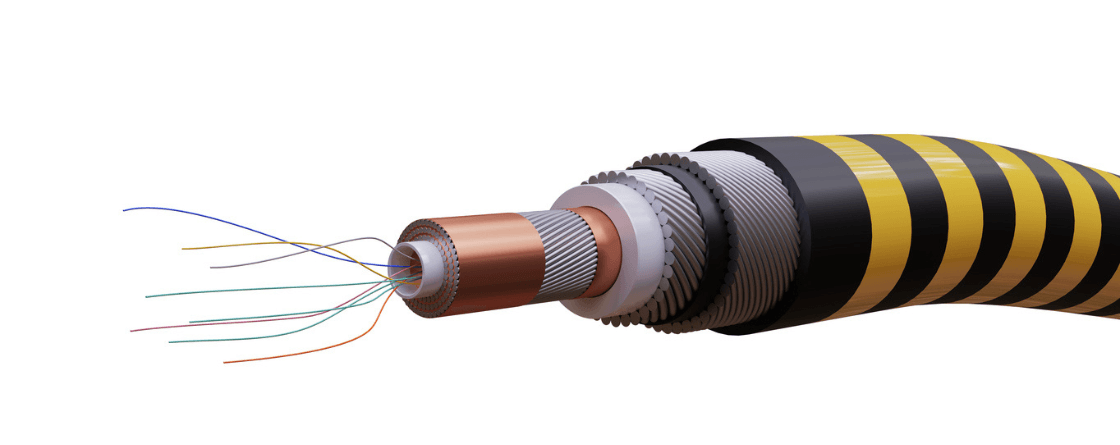

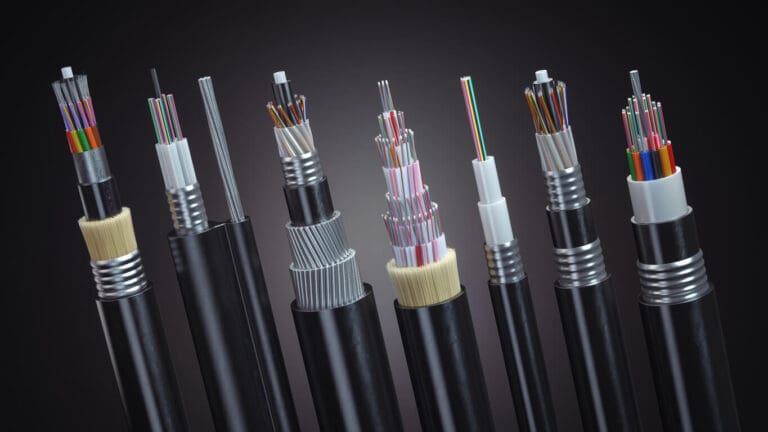

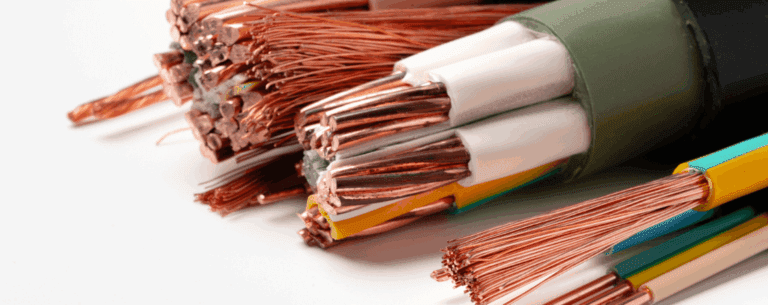

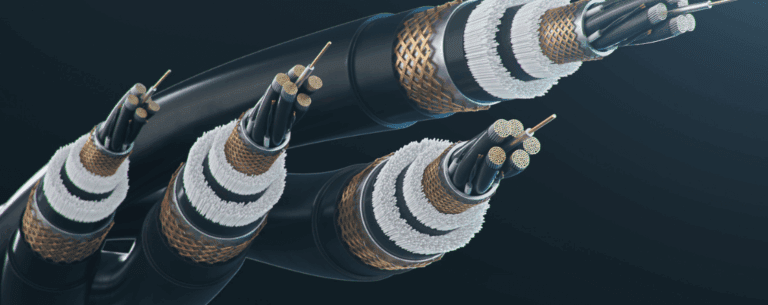

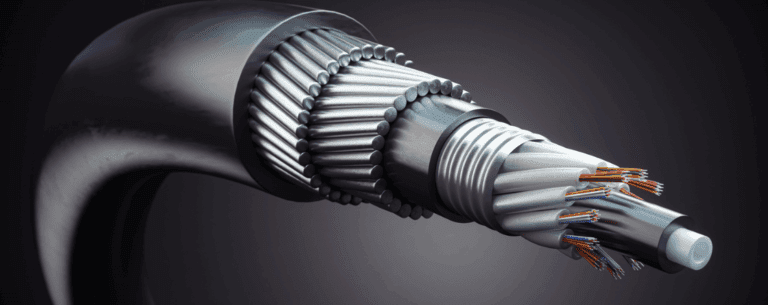

A marine-grade cable is a purpose-built solution that goes beyond a regular cable with extra insulation. Our engineers design these marine cables to withstand the sea’s unique challenges. We begin with tinned copper conductors because we know bare copper corrodes quickly in saltwater. We individually coat each strand with tin, creating a highly effective barrier that stops corrosion before it can even start. Specialised XLPO sheathing then protects the conductors. This high-performance, cross-linked polyolefin is not only inherently resistant to UV and abrasion but also completely impervious to water and chemicals.

This advanced sheathing is often low-smoke, halogen-free, and fire-retardant, adding a crucial layer of safety for enclosed environments. Depending on the application, engineers add additional armouring and screening, such as steel wire braids, to provide an extra physical defence against mechanical stress and shield the cable from electromagnetic interference. For deep-sea applications, a more robust armouring may be used to protect against crushing hydrostatic pressure and impact. The precise combination of these elements is what truly defines a marine-grade cable and its performance.

The difference between a standard cable and an enduring marine-grade solution is a proactive engineering partnership. This is especially true for subsea installations, where failure of marine cables can halt entire operations. A bespoke solution is never an afterthought; it’s the result of a detailed collaboration that starts at the project’s inception. We work with our clients to perform a thorough pre-mortem analysis, identifying every potential point of failure a cable will face throughout its service life.

This includes analysing the specific movements, speeds, depths, and environmental factors a robot or a sensor array will experience. This allows us to select the optimal materials and design the internal structure for a specific “torture test.” This strategic approach is the most cost-effective way to ensure long-term reliability and a predictable Total Cost of Ownership (TCO), as it eliminates the reactive, costly maintenance that comes with off-the-shelf solutions.

A cable failure costs a project far more than the repair. The financial losses from failed marine cables can jeopardize the entire operation. Industry data shows over 80% of all financial losses and insurance claims in the offshore wind sector are directly attributed to these incidents. The breakdown of these costs is staggering, including lost revenue from a wind farm being down, which can amount to millions of pounds a month. Repair and replacement costs are also substantial, with a single repair for an inter-array cable costing between £1 million and £12 million, and up to £30 million for a main export cable. When a failure occurs, you also face the major logistical and financial challenge of hiring specialist vessels and highly skilled technicians. Finally, a failure heavily impacts a project’s risk profile, leading to higher insurance premiums for years to come.

For our marine cables, durability is a certified fact, not merely a claim. We put our products through rigorous, third-party testing to ensure they meet and exceed the most demanding standards, including BS6883, UKOOA, and NEK 606. Our comprehensive testing protocols include water immersion and UV exposure tests, but they go much further. We conduct mechanical fatigue tests to simulate the constant tidal forces and movement of subsea installations, ensuring the cable’s structural integrity over millions of cycles. Pressure resistance tests are performed for deep-sea applications, while salt spray corrosion tests verify the long-term resilience of the conductor coatings. This commitment to testing ensures our cables not only comply but also achieve ultimate endurance. This commitment to uncompromising quality is what truly defines us as a partner.

You’ll find our marine cables at the core of some of the most innovative projects in the marine energy sector. For instance, they are a critical component in offshore wind farms, connecting individual turbines to each other and linking the entire farm to the onshore grid. Our cables also provide crucial power and data connections for sea-surface solar farms as floating solar technology expands. Beyond energy, our cables are essential in marine research, powering critical sensor arrays, data loggers, and underwater ROVs.

Ultimately, a quality cable is the foundation your project needs for longevity, profitability, and safety. That’s the difference we deliver.

Contact GEM Cable Solutions today to discuss how a purpose-built, endurance-engineered cable can secure your project’s future.

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read More

Motorsport teams chase marginal gains in every area of the car, yet many still treat...

Read More

The wiring harness is a high-risk single point of failure in any complex system. If...

Read More

The wiring harness is the highest risk, lowest profile element in flight-critical infrastructure. When your...

Read More

Fibre optic cable is the essential transport mechanism of the modern digital economy. It is...

Read More

Keeping complex systems online takes more than parts and datasheets. It takes cable assembly manufacturers...

Read More

Keeping critical infrastructure online and mission systems ready needs more than components. It requires domestic...

Read More

Selecting a cable supplier is an engineering decision. Experienced engineers know that reliable UK cable...

Read More

Selecting a cable manufacturing partner is an engineering decision, not a price exercise. The right...

Read More

A critical cable assembly fails on a high-speed train. What happens next? The consequences are...

Read More

While electrical safety standards are crucial, they’re only half the story. The physical workmanship of...

Read More

A million-pound robotic system glides into place, its arm extending with flawless precision. Then, it...

Read More

In sectors where precision and safety are non-negotiable, the choice of a cable supplier UK...

Read More

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.