What Does JOSCAR Certification Mean for a Defence Cable Manufacturer?

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

For years, many Original Equipment Manufacturers (OEMs) clung to the belief that total control meant building every component in-house, including intricate cable assemblies.

However, a major shift is underway. OEMs increasingly move away from in-house builds, opting instead for outsourced solutions. Understanding this shift is vital for any OEM navigating today’s competitive landscape and seeking to optimise their production processes.

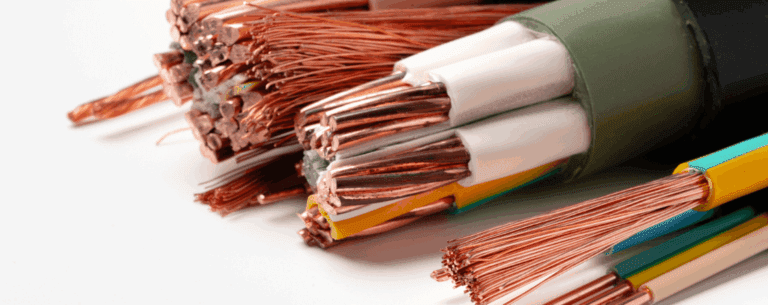

The decision to move away from in-house cable assembly production stems from several practical challenges OEMs face. Maintaining an internal manufacturing operation for something as intricate as wiring harnesses requires significant investment. This includes capital expenditure for specialised equipment, ongoing maintenance, and the constant training of skilled labour.

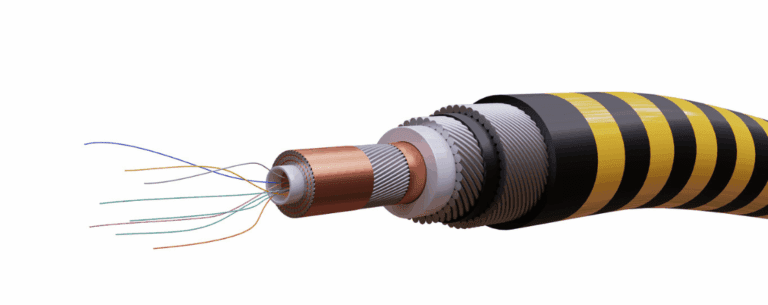

Furthermore, the complexity of modern electronic systems grows exponentially. This demands increasingly sophisticated and precise cable assemblies.

In-use teams also face challenges with scalability. Production spikes or dips can strain internal resources, leading to inefficiencies, increased lead times, or underutilised capacity. OEMs find that managing the entire supply chain, from raw material procurement to final assembly, for components outside their primary product focus becomes a drain on time and expertise.

Outsourcing cable assembly brings several strategic advantages to OEMs. Firstly, it offers access to specialised expertise. Dedicated cable assembly manufacturers possess deep knowledge of materials, design optimisation, and efficient production techniques. This expertise often surpasses what an in-house team can maintain, especially for low-volume, high-complexity, or highly customised solutions.

Beyond just knowledge, expert manufacturers bring advanced testing capabilities and design for manufacturability (DFM) insights. They identify potential issues early, optimising the design for efficient and cost-effective production. This proactive approach minimises costly redesigns; we’ve seen this common pain point plague many in-house operations. It also accelerates product development cycles. They also possess a deeper understanding of niche materials and emerging technologies, which in-house teams might lack.

Secondly, outsourcing enhances efficiency and scalability. External partners can leverage economies of scale, more efficient production lines, and a broader network of suppliers. This translates into faster turnaround times, better cost-effectiveness, and the flexibility to scale production up or down rapidly without impacting the OEM’s internal operations. It also reduces capital expenditure and operating costs, freeing up valuable resources.

Outsourcing allows OEMs to convert fixed costs (equipment, labour) into variable costs, providing financial agility. External partners, specialising in cable assembly manufacturing, manage complex production schedules, ensuring timely delivery even for fluctuating demands. This agility is crucial in fast-paced industries where market windows are narrow. It also simplifies inventory management for the OEM, as the partner handles component sourcing and warehousing.

Finally, outsourcing mitigates risk. Specialised manufacturers manage material sourcing, quality control, and compliance. This reduces the OEM’s exposure to supply chain disruptions, quality issues, and regulatory challenges. It allows OEMs to focus on their core competencies – innovation, product development, and market strategy – while relying on experts for critical component manufacturing.

Ensuring quality in outsourced cable assembly is paramount. Expert partners achieve this through a combination of stringent processes, advanced technology, and unwavering commitment to industry standards. They implement robust quality management systems from design through to final inspection.

Certified manufacturers, like GEM Cable Solutions, adhere to international benchmarks such as AS9100D and ISO 9001:2015. These certifications demonstrate a commitment to excellence, particularly vital for OEMs in aerospace, defence, and other high-precision industries. They also follow industry-specific standards like IPC WHMA-A-620, ensuring superior quality in cable assemblies. This includes meticulous design validation, in-process inspections, and comprehensive final testing. Our decades of hands-on experience in designing, precision manufacturing, and comprehensively testing bespoke cable assemblies equip us to deliver the exacting standards required.

Choosing the right outsourced cable partner is a strategic decision. OEMs should look for a manufacturer with a proven track record of quality and reliability. Key indicators include relevant industry certifications (e.g., AS9100D, ISO 9001, IPC WHMA-A-620) and a strong reputation for performance.

Expertise in bespoke design and manufacturing is also crucial. The partner should demonstrate the ability to handle complex, custom requirements, not just standard products. Assess their engineering capabilities, their approach to project management, and their capacity for comprehensive testing. A partner that offers a “one-stop shop” approach, combining design, manufacturing, and supply chain management, can significantly reduce an OEM’s logistical burden.

Ultimately, the ideal partner acts as an extension of your own team, bringing specialised knowledge and efficiency to your production process.

An ideal partner offers strong DFM capabilities, contributing critical input during the design phase. This ensures the cable assembly is not only functional but also efficient and cost-effective to produce at scale. Look for partners with experienced engineering teams who can collaborate on optimising designs for performance and manufacturability.

Effective outsourcing relies on clear, consistent communication. A good partner provides regular updates, maintains open channels for feedback, and transparently addresses challenges. This collaborative approach builds trust and ensures project alignment.

Evaluate the partner’s supply chain robustness, including their strategies for component sourcing, inventory management, and risk mitigation. For sensitive applications, inquire about their cybersecurity protocols and intellectual property (IP) protection measures. A reliable partner safeguards your designs and data throughout the manufacturing process. Explore our full range of services to see how we can support your needs.

The shift from in-house builds to outsourced cable assembly represents a strategic evolution for OEMs. It allows companies to shed non-core manufacturing burdens and instead focus resources on innovation, research, and market leadership. By partnering with specialised manufacturers, OEMs gain access to unparalleled expertise, enhanced efficiency, greater scalability, and reduced risk. This enables them to bring higher-quality products to market faster and more cost-effectively.

Explore how expert outsourced cable assembly can transform your operations! Contact GEM Cable Solutions today to discuss your project requirements.

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read More

Motorsport teams chase marginal gains in every area of the car, yet many still treat...

Read More

The wiring harness is a high-risk single point of failure in any complex system. If...

Read More

The wiring harness is the highest risk, lowest profile element in flight-critical infrastructure. When your...

Read More

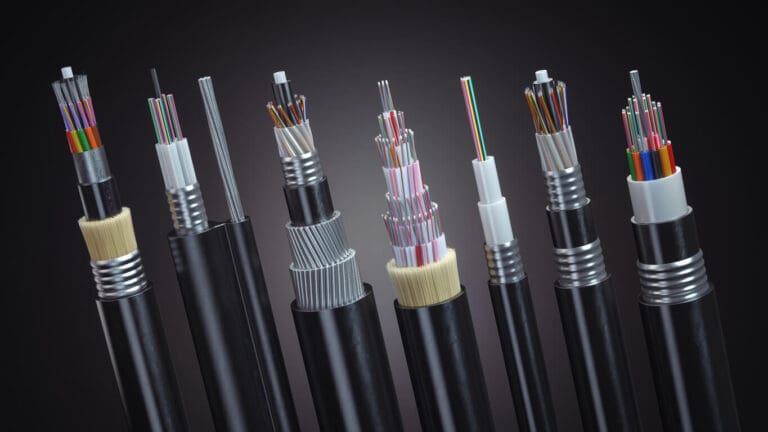

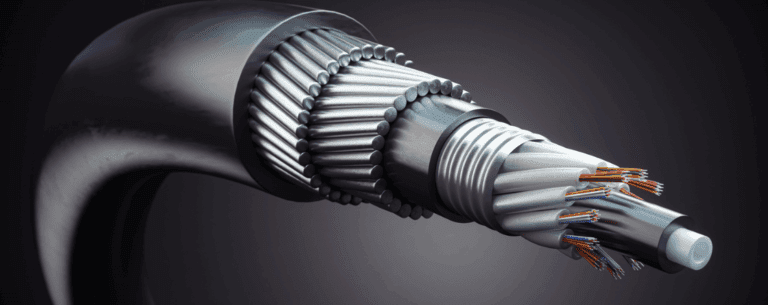

Fibre optic cable is the essential transport mechanism of the modern digital economy. It is...

Read More

Keeping complex systems online takes more than parts and datasheets. It takes cable assembly manufacturers...

Read More

Keeping critical infrastructure online and mission systems ready needs more than components. It requires domestic...

Read More

Selecting a cable supplier is an engineering decision. Experienced engineers know that reliable UK cable...

Read More

Selecting a cable manufacturing partner is an engineering decision, not a price exercise. The right...

Read More

The High Cost of a Single Component A single equipment failure brings a multi-million-pound project...

Read More

A critical cable assembly fails on a high-speed train. What happens next? The consequences are...

Read More

While electrical safety standards are crucial, they’re only half the story. The physical workmanship of...

Read More

A million-pound robotic system glides into place, its arm extending with flawless precision. Then, it...

Read More

When you buy mil-spec cable assemblies for rail projects, you are choosing more than a...

Read More

In practice, defence standard cable solves a large share of wiring-driven reliability issues in modern...

Read More

Unmanned systems now underpin many defence programmes, with air, land and maritime platforms providing surveillance,...

Read MoreReady to talk cables, fibre or full network solutions? Get in touch with our team today, we’re here to help.