THE CUSTOMER

Airbus is a global leader in aeronautics, space and a related services provider, employing a workforce of around 134,000 worldwide. It is a European leader offering the most comprehensive range of passenger airliners, tankers, combat, transport and mission aircraft. Airbus provides the most efficient civil and military solutions, as well as being one of the world’s leading space companies.

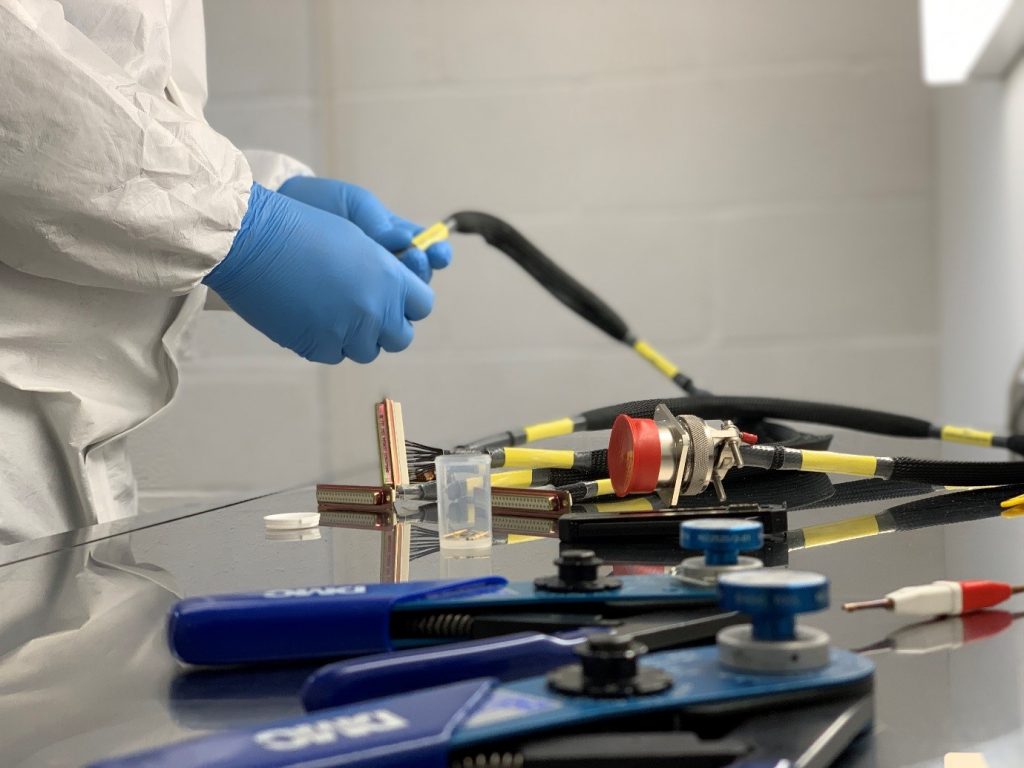

Airbus Defence and Space Bio Clean Room, Stevenage. Copyright: Max Alexander / Airbus.

THE CHALLENGE

Having worked with Airbus on a number of projects over many years. They approached us once again for the Design, Manufacture and Testing of all the required cable assemblies, harnesses and panels for the Mars Rover Project.

Due to the high demands of this project, Airbus appointed GEM Cable Solutions, because of our extensive experience on various complex aerospace, satellite and defence projects and with a successful track record of supporting hundreds of companies through design and build of bespoke products.

Gem Cable Solutions worked closely with Airbus in Stevenage. The focus for Airbus was:

- Design Services

- Precision in Manufacture

- Product Traceability

- Reliability in Products and Materials

- Rigorous testing procedure

- Tight Launch Deadline

The European and Russian space agencies (ESA and Roscosmos, respectively) launched their joint mission on 14 March 2016 to test technology for future exploratory surface missions on Mars.

The ExoMars Trace Gas Orbiter, the first in a series of the two space agencies’ collaborative Mars missions, monitors seasonal changes in the planet’s atmospheric composition and temperature in search for evidence of methane and other atmospheric gases that could be evidence of active biological or geological processes.

This is just the first part of the programme whose ultimate goal is to examine the geological environment and search for life on Mars. ExoMars will also help to prepare for other robotic missions and possible future human exploration.

Its second part, scheduled for 2020, will send the 300 kg. ExoMars rover – a robotic vehicle – to the planet, with the landing scheduled for 2021. Capable of drilling as deep as two metres below the surface, it will search for signs of past or present life. The collected data will help to evaluate risks for future manned missions as well as assist in broader studies of Martian geochemistry and environmental science.

The ExoMars rover currently is under development by Airbus Defence and Space, being built at the company’s UK facility in Stevenage, UK. The rover has been named after Rosalind Franklin, a UK scientist and co-discoverer of the structure of DNA. ExoMars is the first to honour a woman scientist on its flagship discovery craft.

https://www.airbus.com/space/space-exploration/exomars.html

THE SOLUTION

As one of the only independent bespoke cable assembly manufacturers to gain the approval from Airbus, GEM Cable Solutions is able to design, build and test on Airbus Projects to flight standard.

At GEM Cable Solutions, our Engineers and Designers have all been trained to IPC-A-620 standard, giving Airbus confidence that while they focus on the Build of the Mars Rover, they are safe in the knowledge that we are working tirelessly to ensure that all bespoke harnesses, looms and panels were designed, built and tested to the most rigorous of standards and which were delivered on time to meet their tight deadlines.

TESTIMONIAL

“Gem Cable Solutions recently provided Airbus with a variety of test leads and boxes.”

“Gem Cable Solutions were very reactive and professional when late changes/modification were requested from Airbus. The test leads and boxes were made to a very high quality standard, which resulted in Gem Cable Solutions becoming an approved supplier for Airbus.”

Daniel Jones – Airbus Space & Defence